What is PS, and What is it Used For?

Polystyrene (PS) plastic is a naturally transparent thermoplastic that is available as both a typical solid plastic as well in the form of a rigid foam material. PS plastic is commonly used in a variety of consumer product applications and is also particularly useful for commercial packaging. Dow Chemical Company invented a proprietary process to make their trademarked and well-known what is polystyrene foam product “styrofoam” in 1941. The material is somewhat controversial amongst environmental groups because it is slow to biodegrade and is increasingly present as outdoor litter (particularly in the form of foam floating in waterways and the ocean).

The solid plastic form of polystyrene is commonly used in medical device applications like test tubes or petri dishes, or in day-to-day items like the housing on your smoke detectors, the case you used to buy your CDs in, and frequently as a container for foods like yogurt or the red “solo” cup you drink from at a tailgate and/or when you’re losing in a game of beer-pong. The foam form of what is polystyrene is used most often as a packing material. You have probably unpacked a custom styrofoam housing if you’ve ever bought a new television, or a significant piece of new equipment like a Miter saw. Similarly, you’re probably familiar with styrofoam packing “peanuts” used as filler for miscellaneous small items being shipped. Styrofoam is also used for “to-go” containers and disposable tableware from many restaurants.

What are the Characteristics of Polystyrene?

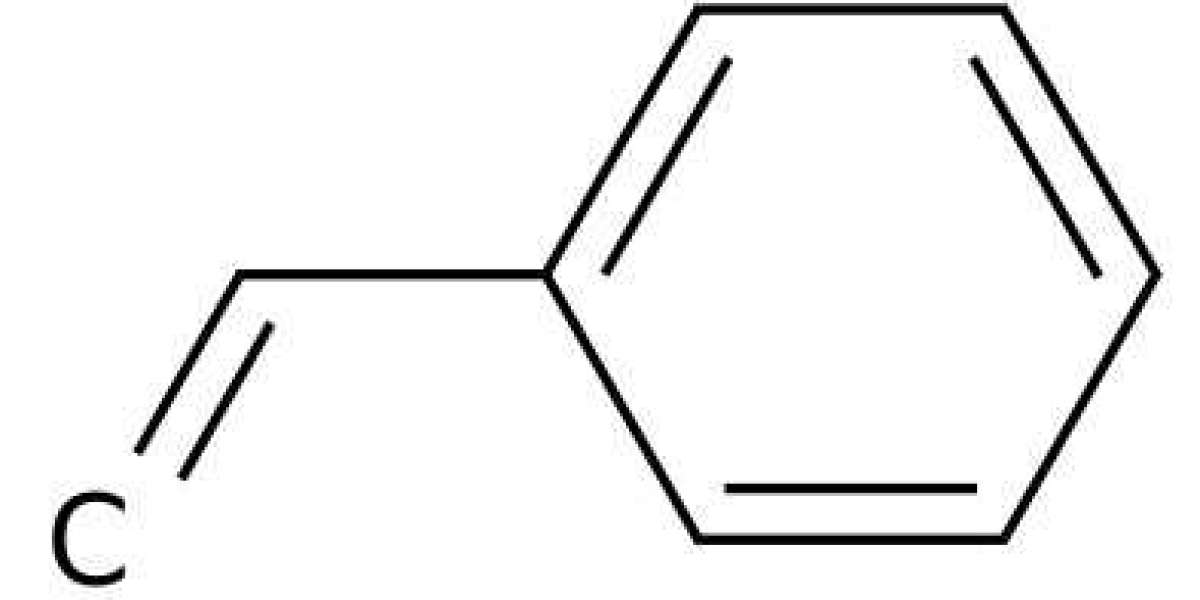

Now that we know what it is used for, let’s examine some of the key properties of Polystyrene. Polystyrene is typically (but not always) a homopolymer meaning that it is composed only of the monomer styrene in combination with itself. Depending on the type of PS it could be classified as a “thermoplastic” or a “thermoset” material. The name has to do with the way the plastic responds to heat. Thermoplastic materials become fully liquid at their melting point (210-249 degrees Celsius in the case of Polystyrene), but they begin to flow at their glass transition point (100 degress Celsius for PS). A major useful attribute about thermoplastics is that they can be heated to their melting point, cooled, and reheated again without significant degradation. Instead of burning, thermoplastics liquefy, which allows them to be easily injection molded and then subsequently recycled. Thermoset plastics, by contrast, will not reliquify once they are “set” in solid form.

By contrast, thermoset plastics can only be heated once (typically during the injection molding process). The first heating causes thermoset materials to set (similar to a 2-part epoxy) resulting in a chemical change that cannot be reversed. If you tried to heat a thermoset plastic to a high temperature a second time it would simply burn. This characteristic makes thermoset materials poor candidates for recycling.

Why is Polystyrene used so often?

Polystyrene is most uniquely useful for its application as a foam. It is the runaway leader in the packaging industry but it also has a wide range of uses as a traditional plastic. At Creative Mechanisms, we have used what is polystyrene in a number of applications across a range of industries. For many years Polystyrene, or as it is often referred to as just Styrene, was used as the go-to prototyping material - basically for the same reasons we now use ABS. It's inexpensive, readily available, white in color, and it glues, sands, cuts, and paints well. The “S” in ABS is Styrene. A lot of older engineers and designers who have been in the industry for a while will ask for a Styrene model when they’re looking for a quick-down-and-dirty prototype. We still have a lot of sheets of Styrene in the shop at Creative Mechanisms. We will use them to make quick test models, paint samples, vacuum formed or thermoformed prototypes, or large models that can be created with flat sheets.

![Narrowband-IoT Market by Solution Type & Deployment Model [2032]](https://youslade.com/upload/photos/2024/12/tiPoJYntLLaLKfbtTcfo_09_4ffd853c21009f8199f78b25effaddff_image.jpg)