Introduction

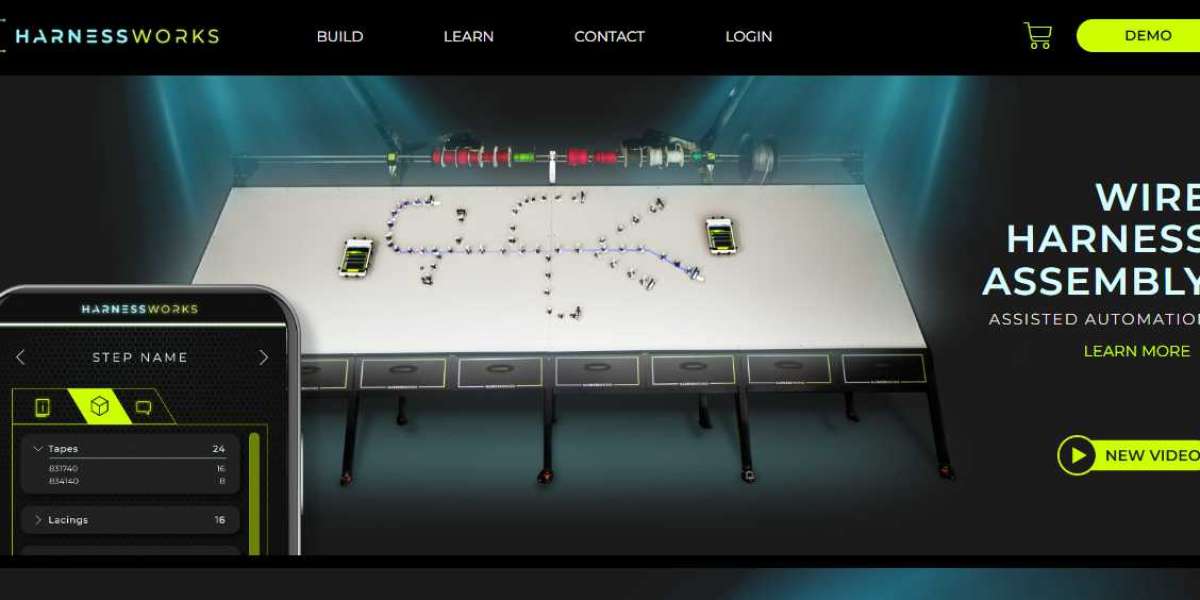

Setting up a wire harness assembly board is a critical step in ensuring powerful and accurate creation of wire harnesses. This guide gives a clear and brief approach to appropriately setting up the assembly board, ensuring that your manufacturing interaction moves along as anticipated.

Outline

Introduction

Background

Step-by-Step Setup Interaction

Preparing the Workspace

Laying Out the Plan Blueprint

Organizing Instruments and Components

Securing the Board

Testing the Setup

Conclusion

FAQs

Background

Wire harness assembly boards are essential in manufacturing industries where accuracy and capability are paramount. These boards give a dedicated workspace to assembling wire harnesses according to unequivocal designs. Appropriate setup is crucial to maximizing the advantages of the assembly board and it is as smooth as conceivable to guarantee that the creation interaction.

Step-by-Step Setup Cycle

1. Preparing the Workspace

Step: Clear the workspace of any messiness and guarantee that there is adequate space for the assembly board and all necessary gadgets.

Importance: A clean and organized workspace diminishes the gamble of mistakes and increases capability during the assembly cycle.

2. Laying Out the Plan Blueprint

Step: Place the wire harness configuration blueprint on the assembly board, aligning it according to the board's markers.

Importance: This gives a clear guide to where each wire and part should be placed, ensuring accuracy during assembly.

3. Organizing Apparatuses and Components

Step: Arrange all necessary gadgets and components (e.g., wires, connectors, fasteners) within easy reach of the board.

Importance: Organized instruments and components reduce the time enjoyed searching for things and assist with maintaining a smooth work process.

4. Securing the Board

Step: Guarantee the board is safely fastened to forestall any advancement during the assembly interaction.

Importance: A stable board is essential for maintaining accuracy, especially while working with intricate or delicate wire harnesses.

5. Testing the Setup

Step: Before starting full-scale creation, direct a trial to guarantee the board is appropriately set up and that all components fit as anticipated.

Importance: Testing distinguishes any setup issues early, allowing for adjustments before actual creation begins.

Conclusion

Setting up a wire harness assembly board appropriately is vital to achieving powerful and accurate creation. By following this step-by-step guide, you can guarantee that your board is prepared for optimal performance, leading to better-quality things and a more streamlined manufacturing process.

FAQs

Q1: For what reason is it important to prepare the workspace preceding setting up the assembly board?

A clean and organized workspace diminishes the gamble of mistakes and guarantees a smooth assembly process.

Q2: How does the plan blueprint help during the setup?

The blueprint gives a visual guide to placing wires and components accurately on the board.

Q3: What is the advantage of organizing apparatuses and components before starting the assembly?

It saves time and decreases interruptions, leading to a more successful work process.

Q4: For what reason is it crucial to get the assembly board?

A stable board forestalls improvement that could lead to misalignment or bungles during assembly.

Q5: What is the motivation behind testing the setup before full creation?

Testing perceives any setup issues early, allowing for amendments before large-scale creation begins.