This method enables complex shapes, small-batch production, and customization to the customer's specifications.

You can start working on it on your own, but doing so successfully requires expertise. Therefore, contracting the work out to a company that offers 3D printing services might be the best option. Because of this, you can also request an instant quote for CNC work online, which is a handy feature. This is typically the most efficient method of production for a British company, which is also the case because of the benefits that will be discussed further down.

What exactly is "3-D printing"?

This manufacturing technique will first be described in detail so that you can gain a better understanding of it before we discuss the many advantages that additive manufacturing holds for businesses. The term "3D printing" refers to a process in which a printer is used to create an object with three dimensions. The object is constructed from different materials, such as plastic, metal, or concrete, one layer at a time. The item is fabricated by the printer on the basis of a three-dimensional model, which is a digital representation of the item. Printing can take anywhere from a few minutes to several hours, depending not only on the printing method used but also on the size of the item being printed.

a limited number of product series

Because of the mold or die that is required, injection molding can be prohibitively expensive for production of low quantities. On the other hand, 3D printing makes it feasible to produce only a limited quantity of your product. Rapid manufacturing is a term that's often used to describe the process of printing individual pieces or customizing products for specific customers. This is even possible. Because of this, you will not have a need for product storage because you will print your products on demand. Because of this, you will not have to spend money purchasing or renting a large warehouse, which will allow you to save money.

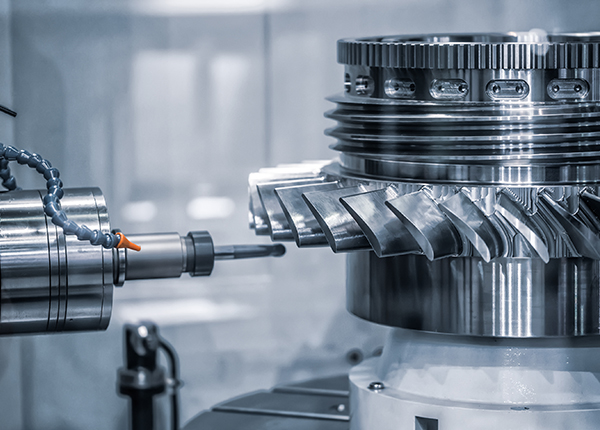

More intricately shaped objects

Complex shapes, such as cavities in an object, can typically be printed using 3D printing in a single pass, although there may be times when support structures are required. This is not always possible with standard methods, such as milling, because they have their limitations. You will frequently be required to construct your product using a number of individual components. An intricate object that has been printed using 3D printing only has one component, making it more durable. Not only that, but this will also result in less waste of the material, which is typically the case with additive manufacturing due to the fact that you will not need to use more material than is required. This will be the case because you will not need to use more material than is required.

Remove mistakes as soon as possible

Additive manufacturing allows you to create a 3D printed prototype of your product in a relatively short amount of time and at a reasonable cost. You will be able to see and feel your product within the next few hours. You will be able to correct any mistakes that may have been made in the design of your product by doing so. You also have the option of making a mold first, and after that you can use injection molding to create a prototype of your product. This is a step that should only be taken once the design of your product is complete and ready to go, as it is both time-consuming and expensive to take. On the other hand, the materials that are used in 3D printing prototypes are very affordable. As was mentioned earlier, a CNC machining service can also create an object with the exact quantity of material that is required, preventing any unnecessary material waste. On top of that, the time required to complete the process is significantly less than injection molding.

Before you go out and buy a 3D printer, the primary consideration you need to give some thought to is what you intend to use it for. The models that are currently available on the market each have distinctive characteristics that set them apart from one another, which are determined by the application. While some of the units are better suited for use in a domestic setting, others are better suited for use in a commercial setting. Before you place your order for the machine, you must first determine the reason you require Aerospace CNC Machining. Make sure that you have a clear idea of what you want to achieve from the beginning of your 3D printing experience if you want to have a positive experience. In this way, you will have the opportunity to purchase a unit that will easily satisfy all of your requirements.

The use of a CNC milling parts is straightforward. They are designed with both practical and protective features, so that you can use any of the alternatives that are currently available on the market with complete peace of mind.

Before making a financial commitment to buy one of the many brands that are currently stocked in retail establishments, it is imperative that you have a solid understanding of the most important features to consider. A successful venture in 3D printing requires, in addition to the printer itself, the materials and software necessary to run the printer. Reviewing your requirements and selecting a printer that has the features that are best suited to your business endeavor are both absolutely necessary steps.

You need to start by asking yourself the fundamental question, "How does the 3D printing process work?"Before investing any money into the company, you will have the opportunity to learn about the requirements of the company through this method. Your ability to make the most informed choice possible regarding your investment is directly correlated to your level of familiarity with the fundamental aspects of the trade. The following paragraphs will go over a few of the most important things for you to think about before purchasing a 3D printer.