The stability of soils, particularly under extreme loads and in areas with weak ground conditions, is critical for the longevity and safety of various projects. Among the most innovative solutions to this problem is the use of geogrids, particularly the Uniaxial geogrid exporters in AhmedabadThis material has transformed the landscape of ground reinforcement, offering a sustainable, cost-effective solution for applications ranging from roadways to retaining walls.

Understanding UNIAXIAL GEOGRID

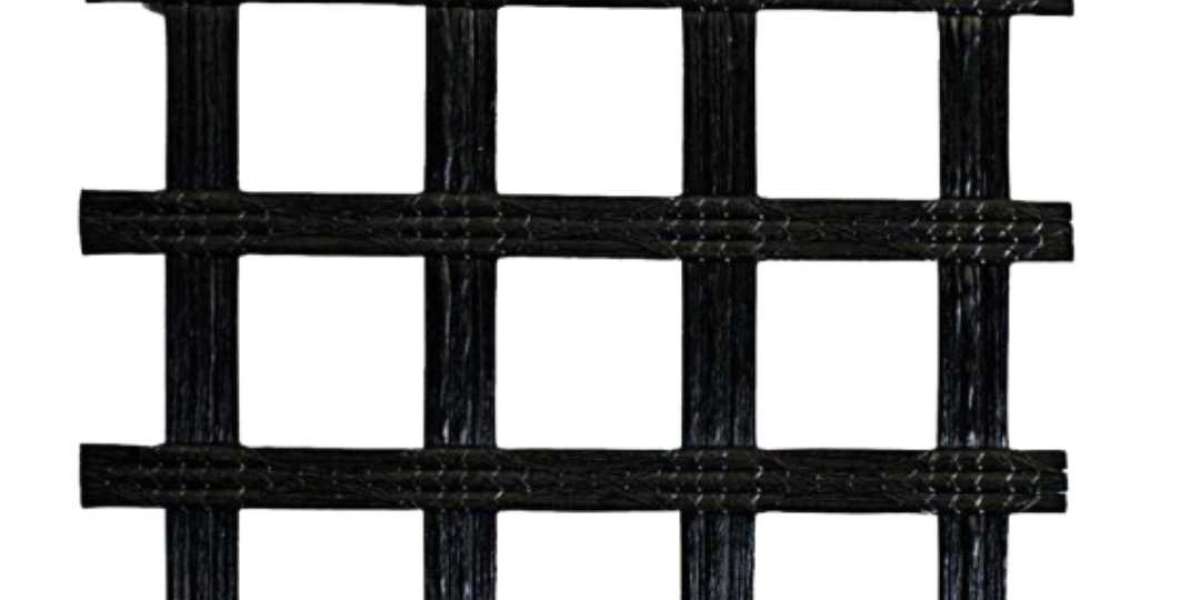

A uniaxial geogrid is a type of geosynthetic material that consists of a polymeric grid structure designed to reinforce soils and improve their load-bearing capacity. Made from high-density polyethylene (HDPE), polypropylene, or polyester, the material features a series of longitudinal ribs connected by transverse ribs. These ribs provide excellent tensile strength, which is critical for ground stabilization. Uniaxial geogrids are primarily used for applications where reinforcement is needed in one direction, which is why they are often applied in road construction, embankment stabilization, and retaining wall construction.

The primary function of a uniaxial geogrid is to transfer loads applied to the ground across a larger area, thus reducing settlement and increasing stability. This makes it an ideal solution for projects where the soil quality is poor or where additional strength is required to carry heavy loads.

Benefits of UNIAXIAL GEOGRID in Ground Reinforcement

The use of uniaxial geogrid offers a host of benefits for ground reinforcement that set it apart from other traditional solutions. Here are some of the key advantages of utilizing this innovative material:

Improved Load Distribution: The main advantage of using uniaxial geogrid is its ability to distribute the load across a larger area. This is particularly beneficial in cases where the ground has low bearing capacity. By spreading the load, the material prevents excessive settlement and helps maintain the integrity of the structure built on top of the reinforced soil.

Cost-Effectiveness: One of the reasons uniaxial geogrids have become so popular is their cost-effectiveness. Compared to traditional methods of ground reinforcement, such as piling or deep foundation systems, geogrids offer a more affordable solution while delivering similar or even superior performance. The reduced need for extensive excavation and other groundwork makes it a practical choice for both large-scale and small-scale projects.

Durability and Longevity: Geogrids, including uniaxial types, are made from robust materials like high-density polyethylene, which is resistant to wear and tear. These materials also offer excellent resistance to UV radiation, chemical degradation, and biological attack. As a result, uniaxial geogrids provide a long-lasting solution for ground reinforcement, ensuring that projects remain stable over the long term.

Ease of Installation: Another notable benefit is the ease with which Uniaxial geogrid manufacturers in Ahmedabadcan be installed. Their lightweight nature and flexible design allow for quick and straightforward placement in the ground. This reduces the time required for installation, lowering labor costs and speeding up project completion.

Environmental Benefits: Uniaxial geogrids contribute to environmentally friendly construction practices. The reduction in the amount of soil disturbance, combined with the durability of the material, makes it an eco-friendly alternative to other reinforcement methods. The long lifespan of the geogrid reduces the need for frequent maintenance or replacement, leading to a reduction in resource consumption over time.

Applications of UNIAXIAL GEOGRID

Uniaxial geogrids have found wide application in various sectors of the construction industry, from highways to railroads, embankments, and even in landscaping. Some of the key applications include:

Road and Highway Construction: One of the most common uses of uniaxial geogrid is in the construction of roads, highways, and railways. In such projects, the material helps prevent the displacement of soil under traffic loads, thereby reducing the risk of cracks, deformations, or rutting. By improving the stability of the subgrade, uniaxial geogrid ensures smoother, more durable road surfaces.

Retaining Walls and Slope Stabilization: Uniaxial geogrids are often used to reinforce retaining walls and slopes. These geogrids provide the necessary tensile strength to hold the structure in place, preventing soil erosion and supporting the stability of the wall. This application is particularly important in areas with high slopes or unstable soil conditions.

Embankment Construction: In embankment construction, where the soil must support significant loads, uniaxial geogrid helps to maintain stability by distributing forces over a wider area. This is especially useful when dealing with weak soils that may not naturally support large loads.

Landfills and Waste Management: Geogrids are also used in landfill sites for reinforcement purposes. These materials help improve the bearing capacity of the soil and prevent excessive settlement over time, a critical factor in the long-term stability of landfill sites.

UNIAXIAL GEOGRID EXPORTERS AND MANUFACTURERS IN AHMEDABAD

As demand for quality ground reinforcement solutions grows, many businesses are stepping up to meet the need. In Ahmedabad, one of India's major industrial hubs, uniaxial geogrid exporters and manufacturers play a crucial role in the supply of these materials. With expertise in producing high-quality geogrids, these companies supply various industries, including construction, transportation, and waste management, with the materials they need to ensure stable and long-lasting ground reinforcement solutions.

Ahmedabad is home to some of the leading uniaxial geogrid manufacturers in India, known for their ability to produce products that meet international quality standards. These manufacturers focus on continuous innovation to improve the strength and durability of their geogrids, ensuring they are suitable for a wide range of applications.

Conclusion

The uniaxial geogrid is a groundbreaking solution in the field of ground reinforcement. Its ability to distribute loads effectively, coupled with its cost-effectiveness, durability, and ease of installation, makes it an invaluable material in modern construction projects. Whether used in road construction, retaining walls, or embankments, Uniaxial geogrid exporters in Indiaprovide superior strength and stability, helping ensure the longevity and safety of the infrastructure built on them. As the demand for high-quality ground reinforcement solutions continues to rise, the role of uniaxial geogrids in transforming construction practices cannot be overstated.

With top-tier manufacturers and exporters in Ahmedabad and across India, access to these materials has never been easier. The future of ground reinforcement looks brighter with the continued advancement and adoption of uniaxial geogrids.

Frequently Asked Questions (FAQ)

What is the difference between uniaxial and biaxial geogrids?

Uniaxial geogrids are designed to provide reinforcement in a single direction (usually longitudinal), making them ideal for applications where strength is needed primarily in one direction, such as for retaining walls and roadways. Biaxial geogrids, on the other hand, offer reinforcement in both horizontal and vertical directions, making them suitable for applications where strength is needed in multiple directions, such as base stabilization.How long does a uniaxial geogrid last?

The lifespan of a uniaxial geogrid depends on factors like soil conditions, climate, and the specific type of material used. However, in general, uniaxial geogrids are highly durable and can last for decades, offering long-term stability and reduced maintenance costs over the lifetime of the reinforced structure.Can uniaxial geogrids be used in areas with poor soil conditions?

Yes, uniaxial geogrids are particularly beneficial in areas with poor soil conditions. They enhance the load-bearing capacity of the soil, prevent excessive settlement, and help stabilize weak or loose soils, making them an ideal solution for construction in challenging ground conditions.