Thermally conductive adhesive has become an essential component in industries that require efficient heat management. From electronics to automotive and renewable energy, this innovative material plays a vital role in ensuring optimal performance and longevity of critical components.

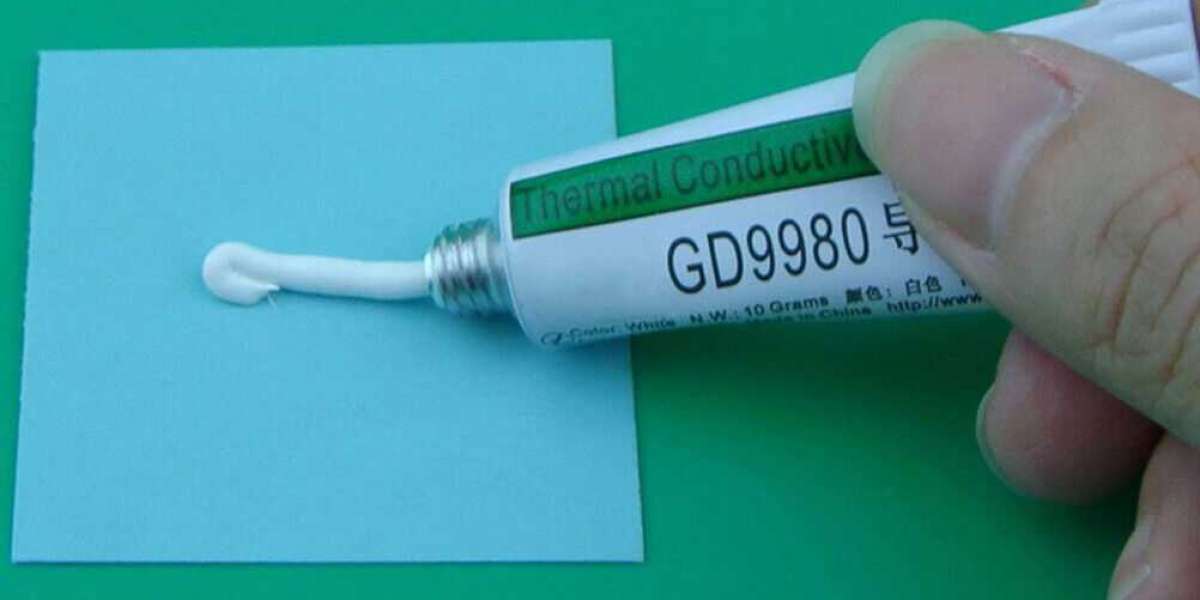

This specialized adhesive is designed to bond surfaces while effectively dissipating heat. It is widely used in electronic devices like CPUs, LEDs, and power modules, where heat can compromise functionality and reliability. By providing excellent thermal conductivity, it helps reduce the risk of overheating, ensuring the stability and efficiency of the device.

In the automotive sector, thermally conductive adhesive is used in electric vehicle batteries and powertrain systems to enhance thermal management and improve performance. Similarly, in renewable energy systems, it aids in managing heat in solar panels and wind turbines, contributing to sustainable energy production.

One of the key benefits of thermally conductive adhesive is its ability to simplify assembly processes. Unlike traditional mechanical fasteners, it provides a strong bond while offering thermal conductivity, reducing the need for additional components.

Whether you’re in electronics, automotive, or renewable energy, choosing the right thermally conductive adhesive is crucial. Look for adhesives with high thermal conductivity, strong adhesion, and compatibility with your application.

Investing in high-quality thermally conductive adhesive ensures efficiency, safety, and durability for your projects. Optimize your systems today with this game-changing material.