Priority should be given to the benefits that come with air-driven liquid pumps. Which are:

There is no need for electricity, and any inert gas can be used to power it.

can run continuously at full load without overheating or consuming power.

When working hard, keep your cool to avoid driving air expansion at the exhaust.

Due to their ability to maintain high pressures over an extended period of time, air-driven liquid pumps make excellent Pressure Test Pumps.

Versions equipped with liquid end pistons, as opposed to plungers, are more effective for pumping gaseous liquids (Giquids), such as refrigerant and fire-fighting agents, and they are also capable of producing a lot of vacuum (negative) pressure.

Plunger types are capable of reaching and maintaining extremely high liquid (hydraulic) pressures.

Industries having applications for pressure testing include the diving industry, which has standards for approving divers' air bottles and gear.

Certification standards for storage containers, tanks, and related machinery are set down by the LPG/CNG industry.

Extinguishers and related equipment must be certified by the firefighting industry.

Gas storage containers, tanks, and related pipework and equipment must be certified by industrial gas manufacturers and suppliers.

producers of pressure vessels that need testing and certification.

those who install oil and gas pipelines that need to be tested and certified before usage.

producers of pipes, fittings, and tubes.

Hose manufacturers and suppliers, including those for hydraulics.

the Defense Industry

Uses for fluid transfer in several industries:

Firefighting industry using CO2 extinguisher filling.

With the evacuation and refilling of refrigerant systems in the refrigeration and air-conditioning industry.

Defense Industry

Applications requiring a non-electric high-pressure hydraulic source fall under the category of "other applications."

Applications for hydraulic and isostatic presses that are high and very high.

For an emergency non-electric high-pressure hydraulic source, offshore oil and gas platforms are needed.

fluids in hazardous areas to pump.

to dispense dangerous fluids.

for the purpose of providing hydraulic pressure for various in-field jacking applications.

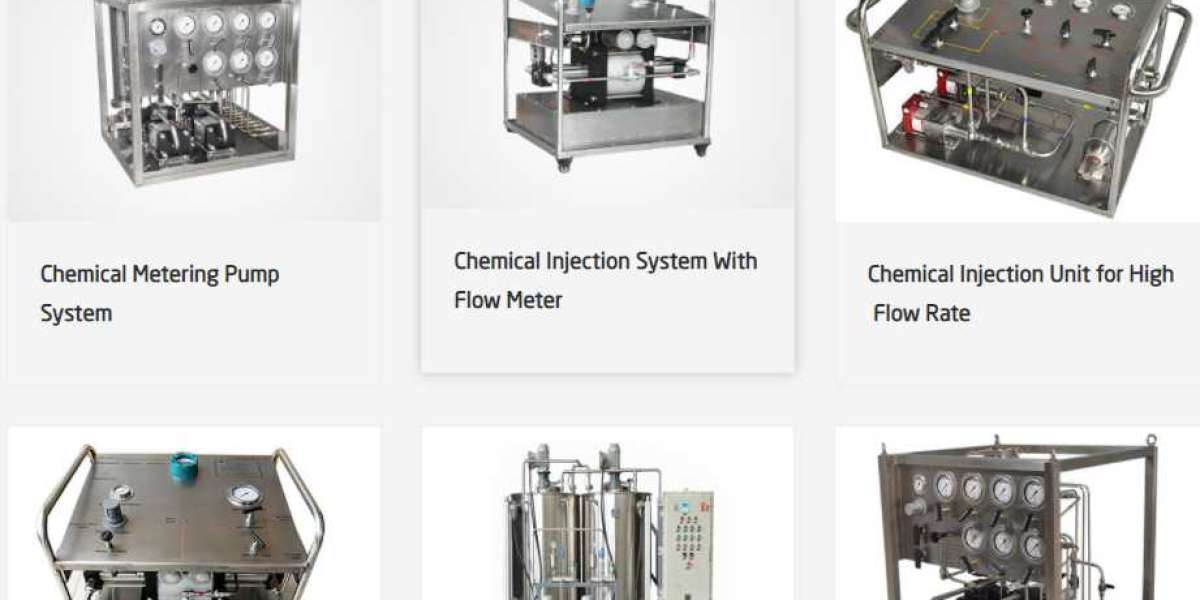

Providing Chemical Injection Pumps for Upstream Oil and Gas Collecting Systems with Dust Suppressant Fluids in Open and Underground Mines.

At downstream oil and gas plants as chemical injection pumps.