Custom food paper is not merely a wrapper in the case of food packaging; it forms part of the customer experience. Paper weight is one of the critical factors that define how well or how badly it performs. The choice of paper weight not only influences the quality of protection of the foodstuff and its freshness, but also that of the brand. A paper that is too thin may also get torn up, and a thick paper may become too costly. Companies have to find the middle ground between the tastes, the purpose, and the budget. This chart talks you through the necessity of the correct weight selection and what must be taken into consideration regarding the kinds of food and purposes. Now, let us see how the right food paper weight can get your food service presentation up to the next level.

Spending on knowing the Weight of Paper inside Food Packaging

The thickness or the density of the material is known as the paper weight, and it is commonly measured for its thickness in GSM (grams per square meter). The greater the GSM, the thicker and resistant the paper. Based on the temperature of the food, the moisture content of the food, and the grease content, as well as the packaging system, a food may be packaged in one weight or another. As an example, some lightweight weights such as 25-40 GSM would be appropriate to use on light products or food such as cookies or pastries, whereas heavier weights such as 60-80 GSM are good with grease or hot foods. The type of food and the condition of serving ought to be identified before selecting a weight to eradicate underperformance. Lightweight may be ideal when it comes to the custom food paper bags in bakeries or cafes, where the items are dry.

The Importance of Paper Weight when Wrapping Food

Food wrapping depends mainly on the durability of the material. A paper sheet can also rip in moisture environments or greasy areas, causing a mess and a bad customer experience. When food is being handled and transported, paper weight can maintain the integrity of the food. Moreover, it also influences the quality of the print made- the thicker the paper, the more ink it can absorb, and the better it looks at your design. Thus, knowledge of this factor is crucial in investing in custom food-paper wrap, especially with take-out and delivery services, where insulation and durability are the most important factors.

Finding the Correct Composition of Flexibility and Weight

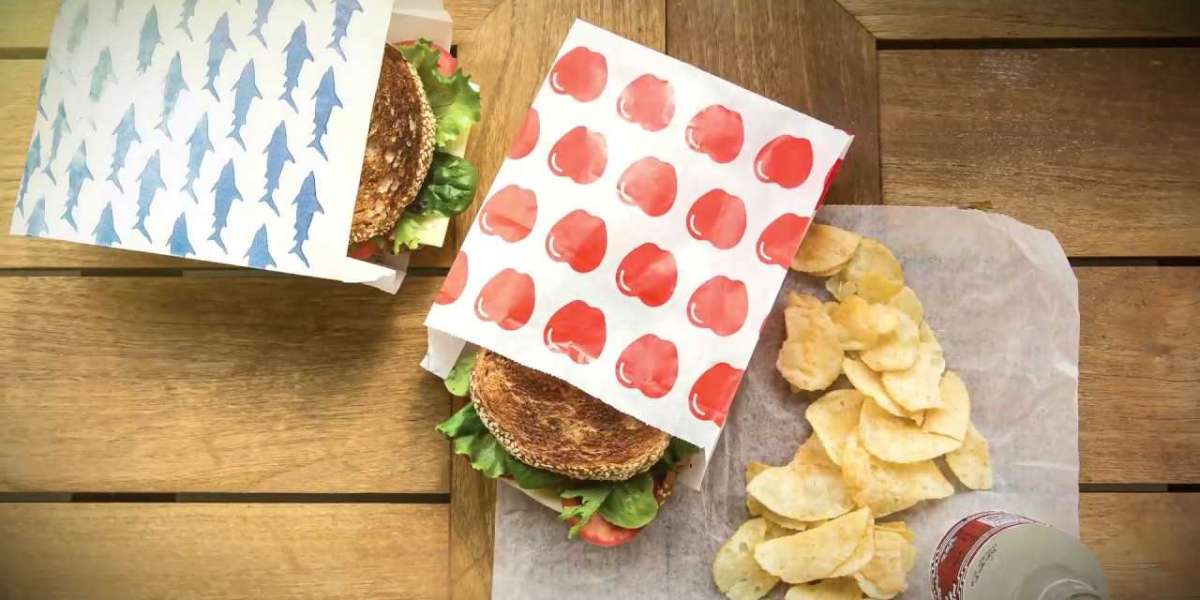

A greater weight of food paper makes it durable, yet it may not be easy to wrap delicate products. Thinner paper, on the contrary, is less protective and more pliable. This trade-off contributes substantially to usability with regard to sandwiches, wraps, or fries. Consider the way and style you must fold or wrap the paper, and how the food is going to be served or kept. For restaurants in which various types of food are wrapped every day, the middle-quality sheets of food paper (such as paper with a thickness of 40-50 GSM) will be compromised, allowing the operation of a broad range of products.

Food Safety and Grease Resistance Factors

In packaging greasy and oily products such as burgers and fried snacks, a higher GSM is not sufficient. You will prefer a grease-proof and food-safe paper. Another layer of protection is with wax-coated or laminated versions. This is more so when it comes to fast foods and casual dining, where first impressions matter the most. Personalised printing on food paper, which gives both the aesthetic look and functionality does not only advertises your brand, but also instills confidence into the mind of the consumer about the safety and quality.

Selection Paper Weight According To Food Temperature

Low-weight papers are susceptible to low-weight, or being smelted by hot foods, as the material was not created with high temperatures in mind. As an illustration, the hot deli products or hot-off-the-grill products must use higher GSM, which does not dissolve on heat. Thickness should always be measured in combination with heat tolerance. In places or food like food trucks or diners serving hot food, custom wax food paper is one of the best, which avoids leakage but keeps the food hot as well and maintains its shape.

Aesthetics And Environmental Sustainability Of Paper Weight

The modern customer is concerned about the environmental implications. A more substantial paper may seem awarser, and more high-priced, yet it consumes more resources. Do you also make sustainability part of your brand mission? Then find recycled or compostable alternatives with good characteristics at lighter weights. You may still attain a rustic and environmentally friendly theme with custom food brown paper that goes well with natural or organic food companies. These papers are commonly available in 35-50 gsm, offering an excellent combination of eco-friendliness and usefulness.

The Time to Use Rolls Instead of Pre-Cut Sheets

The purchase of bulk quantities is usually beneficial to businesses that would consume a high volume of food or require a special package design. Paper rolls are more flexible and minimize wastage as one may cut to his or her size. This would especially be useful on products with odd shapes or those that have constant changes in package design. Getting a custom food paper roll in the weight that suits your line of products assists in getting the wrapping standard,dised as well as leaving you with the ability to continue being efficient during those peak periods.

Last Notes on Choosing an Ideal Paper Weight

The weight of the paper is not an exclusive technical matter; it determines the security of your product, its look, and even customer satisfaction. The proper thickness will also make your food stay intact, clean,,n and presentable on the way out of your kitchen to the customer. Regardless of whether you require a light and breathable or a thick and grease-resistant one, the knowledge about its use and necessity should allow you to choose the best option. A proper fit between custom deli paper wrap depicts professionalism and responsibility, bubuildsour brand, and brings assurance to customers.

Conclusion

The choice of weight that you give your custom food paper is a subtle call that has implications on performance as well as perception. Whether it is using light ounces of paper on bakery products, bulky rolls of greasy meals, the application has a different need. Taking into consideration food type, temperature, and, , I'm age and environmental issues makes you not only wrap up, but also smartly. Never leave without trying your alternatives and opinions of customers to perfect your decision. Your packaging can not only help to protect, stunning, and add value to your brand experience, but it can also be designed with a tailored approach toward paper weight. Memorability of your “food” begins with the paper it is wrapped in.