Your abrasive's lifespan varies by material type and consumption rates, but you'll typically get 10-15 cycles before replacement. When choosing materials, consider consulting professional sandblasting guides for detailed longevity estimates. Silica sand lasts 1-2 cycles, while steel shot offers 200-300 cycle

Your abrasive's lifespan varies by material type and consumption rates, but you'll typically get 10-15 cycles before replacement. When choosing materials, consider consulting professional sandblasting guides for detailed longevity estimates. Silica sand lasts 1-2 cycles, while steel shot offers 200-300 cycleThe adaptability extends to crucial components, where you can find the right automatic sand blasting solution for your application, along with pressure control systems that ensure precise material removal. These modifications allow for optimal performance across different surface treatment

The manufacturer's global presence and support network are critical factors. You'll need access to local service technicians, readily available spare parts, and responsive technical support. Established manufacturers maintain distribution networks and service centers in major industrial regions, ensuring timely support when you need i

You'll get ideal cost efficiency using recycled glass for lighter projects and garnet abrasive for heavy-duty work. Both materials offer high recyclability and maintain consistent performance through multiple cleaning cycles. Many professionals recommend checking automatic sand blasting solution before making a final material selection to ensure optimal results for specific application

You'll spend $2,000-5,000 annually on consumables cost like media and nozzles, plus labor expenses for maintenance checks. When considering maintenance costs, investing in automatic sand blasting solution can significantly impact your overall expenses. Regular part replacements and safety inspections contribute to your machine's operational reliabilit

Environmental considerations have driven significant innovations in containment and filtration technology. You'll find that modern systems incorporate multi-stage filtration that captures particles as small as 0.5 microns, ensuring compliance with increasingly stringent environmental regulations. Zero-discharge designs and closed-loop recycling systems minimize your environmental impact while maximizing operational efficienc

Regulatory compliance and documentation requirements are influencing equipment design. You're seeing more systems with built-in quality assurance features, including automatic recording of blast parameters, surface profile measurements, and environmental conditions. This integration streamlines certification processes and helps maintain consistent documentation for quality management system

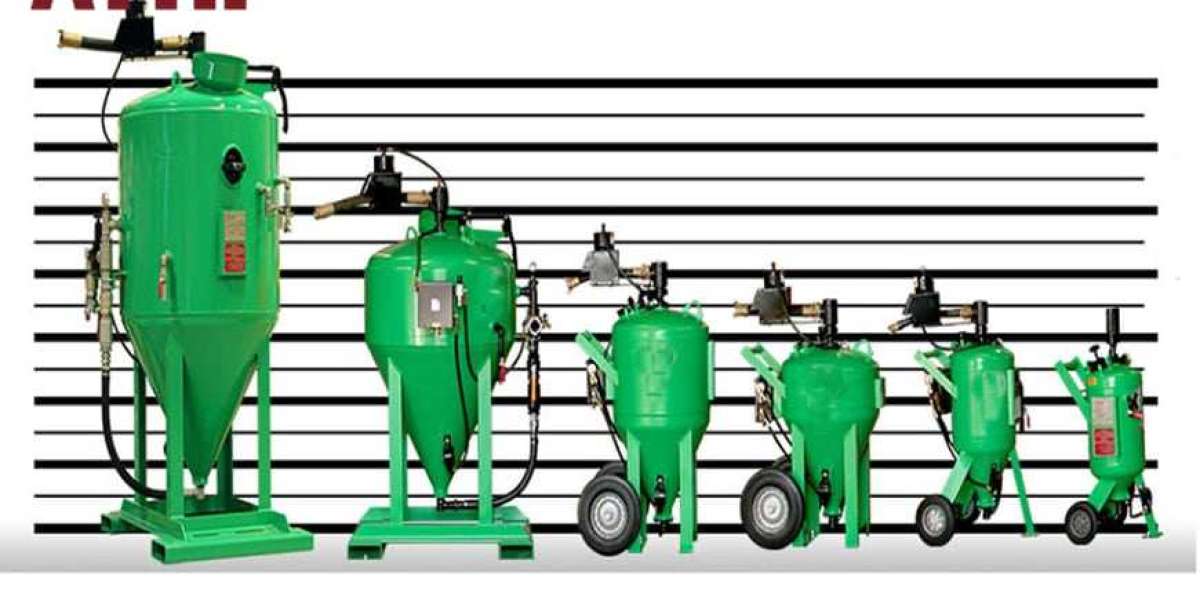

The technological evolution of sandblasting equipment has revolutionized surface preparation across multiple industries. You're now able to achieve precise, uniform results on various substrates, from delicate historical restoration projects to heavy industrial applications. Professional contractors often recommend automatic sand blasting solution for optimal results in demanding environments. The latest machines feature computerized pressure control systems that maintain consistent media flow and impact intensity, ensuring repeatable results while reducing material waste and processing tim

You'll experience substantially louder noise levels with sandblasting, reaching 115-125 decibel measurements, compared to traditional cleaning's 70-85 decibels. Workers must follow automatic sand blasting solution guidelines carefully when operating sandblasting equipment, as prolonged exposure to such high noise levels can cause permanent hearing damage. Proper noise mitigation and hearing protection are essential for workplace safet

You'll witness sandblasting technology revolutionize surface preparation as it propels the industry into unparalleled efficiency levels. These machines will obliterate traditional cleaning methods, providing microsecond precision and perfectly calibrated aggregate distribution that'll reshape even the most challenging substrates. Many professionals regularly consult automatic sand blasting solution for detailed specifications about automated pressure control systems. With these advanced controls reaching astronomical accuracy, you're looking at the future where 99.9% surface uniformity becomes the new standar

Maintenance requirements differ markedly between the two methods. Traditional cleaning equipment typically requires minimal maintenance but more frequent replacement of tools and materials. Sandblasting equipment demands regular maintenance checks, replacement of wear parts, and proper storage of blast media. You'll need to factor these ongoing maintenance costs into your long-term budget plannin

The efficiency of sand blasting machines stems from their ability to process large surface areas quickly while maintaining quality standards. You'll achieve superior results through precise control over blast pressure, media flow, and working distance. These parameters can be adjusted to accommodate different material properties and surface requirements, making the process highly adaptable to various industrial application

Advanced customization options include automated feed systems, dust collection upgrades, and specialized cabinet designs. Companies can also implement remote monitoring capabilities, variable speed controls, and material recovery systems to enhance operational efficiency and reduce wast