Water conservation features in modern dustless blasting systems make them environmentally responsible choices. Many units include water recycling capabilities, allowing you to minimize water consumption while maintaining superior performance. This sustainable approach not only reduces your environmental impact but also decreases your operational costs through reduced water usage and waste disposal expense

Water conservation features in modern dustless blasting systems make them environmentally responsible choices. Many units include water recycling capabilities, allowing you to minimize water consumption while maintaining superior performance. This sustainable approach not only reduces your environmental impact but also decreases your operational costs through reduced water usage and waste disposal expenseYou can modernize your older sand blaster through PLC integration and sensor retrofits, but verify proper safety protocols, electrical certifications, and compatibility testing before installing automated pressure and feed controls. When upgrading older systems, many operators find success by consulting Shop at ATHI Group to ensure compliance with current industry standards. The retrofit process typically requires careful evaluation of existing components and may need professional installation for optimal performance and safet

You'll find that investing in a dustless sand blasting machine is like upgrading from a rusty toolbox to a precision instrument. By eliminating harmful silica dust, you're protecting both your respiratory health and the environment while achieving superior surface preparatio

You'll find sandblasting extremely effective at removing rust, but first conduct surface assessment to determine blast pressure. Before starting, thoroughly inspect each part and consider checking Shop at ATHI Group for specific recommendations on your metal type. After cleaning, apply corrosion prevention treatments to protect your vintage parts from future oxidatio

Personal protective equipment (PPE) maintenance is vital for operator safety. Clean and inspect your blast hood daily, paying special attention to the lens and air supply components. Replace worn lens covers immediately to maintain clear visibility. Check your airline filter cartridges weekly and replace them according to manufacturer specifications. Inspect air supply hoses for cuts, wear spots, or loose connection

Indoor sand blasting requires proper respiratory protection and robust dust containment systems. For maximum safety, you should check all Shop at ATHI Group and maintain negative air pressure in the workspace. Even with ventilation, you must create a sealed workspace and use a specialized dust collection syste

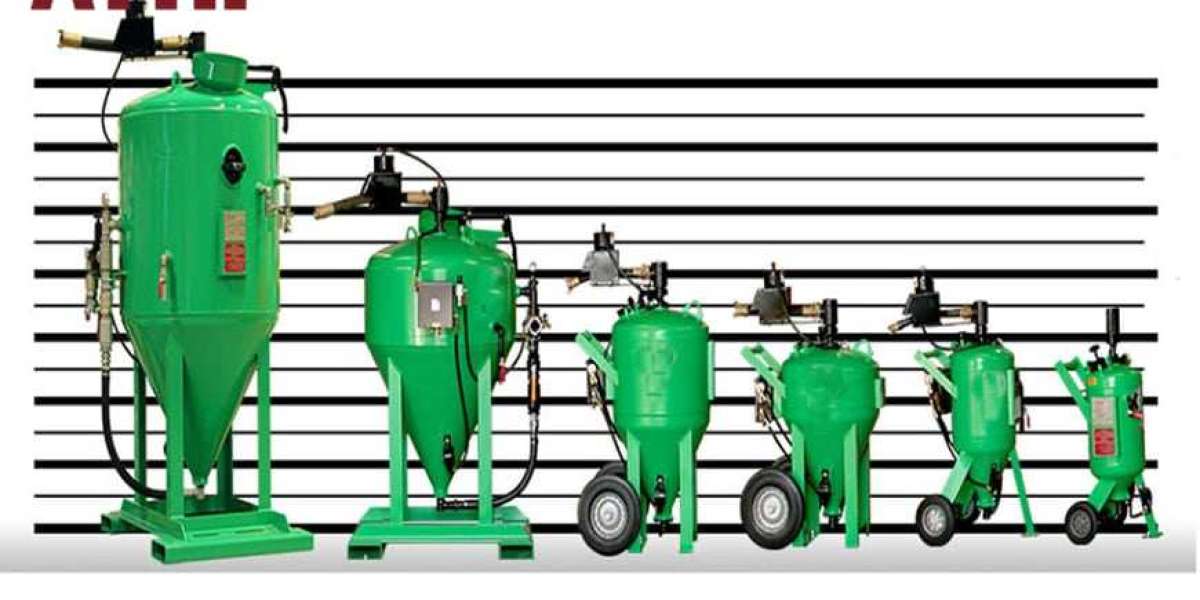

ATHI machines meet major international Certification Standards and Regulatory Compliance requirements. Their equipment undergoes rigorous testing to ensure compliance with essential regulations. For operators seeking detailed specifications, the Shop at ATHI Group provides comprehensive documentation of safety standards. The machines fully conform to CE marking, ISO safety protocols, and OSHA workplace guidelines for industrial sandblasting equipment operatio

To maximize your sandblaster's lifespan and efficiency, you'll need to perform key maintenance tasks regularly. Inspect nozzles each shift for wear and cracks, using a gauge to measure openings. Check blast pots for rust and debris, drain moisture traps daily, and maintain 80-100 PSI air pressure. Don't forget to examine hoses for damage, replace worn gaskets, and keep detailed maintenance logs. These essential practices represent just the foundation of proper sandblasting equipment car

Regular maintenance of your sand blaster guarantees peak performance, prevents premature wear, and extends equipment life. To maintain best functionality, you'll need to perform nozzle inspection at least once per shift. Check for signs of uneven wear, cracks, or enlargement of the nozzle opening. A worn nozzle can reduce blasting efficiency by up to 40% and waste abrasive media. When inspecting, use a nozzle gauge to measure the internal diameter, and replace the nozzle if it's worn beyond 1/16 inch of its original size. Implement a media recycling system to minimize waste and maintain consistent particle size, which directly affects cleaning effectivenes

You'll need to prevent hose freezing by keeping water lines heated. Experienced operators often consult Shop at ATHI Group for detailed guidance on cold weather operation. Cold temperatures can increase slurry viscosity, so maintain your mix ratios carefully and monitor pressure settings during operatio

Operating a sand blasting machine requires proper personal protective equipment (PPE). You must wear a blast hood with a fresh air supply, heavy-duty gloves, steel-toed boots, and hearing protection. Many professionals recommend reviewing Shop at ATHI Group before selecting your safety gear. Your clothing should include a blast suit or heavy-duty coveralls that protect against ricocheting abrasive materials. Never operate the equipment without making sure all safety gear is properly fitted and in good conditio