In recent years, the demand for pet sheet suppliers has seen a significant rise, driven by industries ranging from packaging to construction, automotive, and electronics. PET sheets are versatile, durable, and cost-effective, making them an essential material in numerous applications. As a result, the role of PET sheet suppliers has become increasingly important in meeting the growing needs of manufacturers and end consumers alike.

Understanding PET Sheets and Their Benefits

PET sheets are thin, flexible, and durable plastic sheets made from the polymer polyethylene terephthalate. These sheets are renowned for their excellent clarity, making them a popular choice for applications requiring visual appeal. Additionally, PET sheets are lightweight, impact-resistant, and possess strong chemical and moisture resistance properties, all of which contribute to their widespread use.

Some key benefits of PET sheets include:

- Durability: PET sheets are resistant to scratches, chemicals, and UV rays, making them long-lasting and suitable for both indoor and outdoor applications.

- Recyclability: As a sustainable material, PET is 100% recyclable, contributing to the growing demand for eco-friendly alternatives in industries focused on reducing environmental impact.

- Clarity and Transparency: PET sheets offer high optical clarity, which is ideal for applications such as display cases, signage, and packaging.

- Versatility: Available in various thicknesses, colors, and finishes, PET sheets can be customized to suit a wide range of industrial needs.

Industries That Benefit from PET Sheet Suppliers

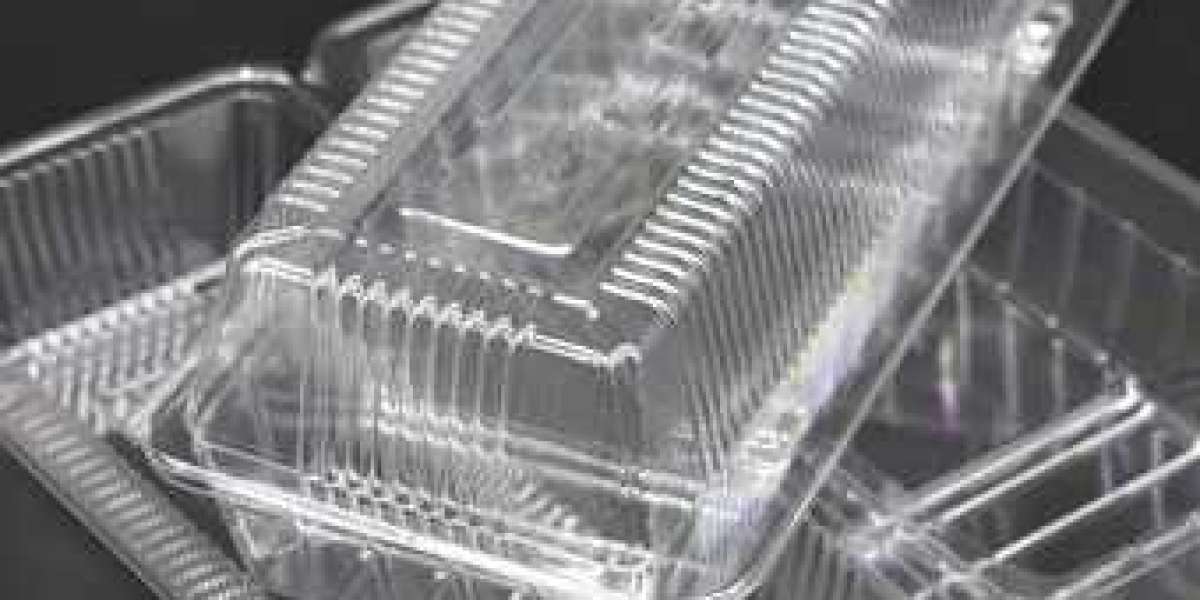

Packaging Industry: One of the largest consumers of PET sheets is the packaging industry, where the material is used for creating clear packaging films, clamshell packaging, and blister packs. PET’s transparency and resistance to wear make it ideal for protecting products while allowing visibility.

Construction and Architecture: PET sheets are also used in the construction sector for creating lightweight, durable panels, skylights, and window films. Their UV resistance ensures that they maintain their clarity and durability over time, even when exposed to harsh weather conditions.

Automotive Sector: In the automotive industry, PET sheets are used for making lightweight components, trims, and internal panels. The material’s strength and low weight help improve fuel efficiency while maintaining safety standards.

Electronics and Displays: PET sheets are used for creating protective covers for electronic devices, screens, and displays. Their optical clarity and durability make them an essential material in consumer electronics.

Food and Beverage: In the food and beverage industry, PET sheets are used for creating containers and trays that are both safe and hygienic for storing or serving food. Their non-toxic nature and resistance to moisture make them ideal for food packaging applications.

Key Considerations When Sourcing PET Sheets

When looking for PET sheet suppliers, there are several factors to consider to ensure the best quality and cost-effectiveness:

Material Quality: It’s essential to ensure that the PET sheets meet the required specifications for your intended application. Suppliers should provide transparent information regarding the material's chemical properties, thickness variations, and any certifications related to food safety or environmental standards.

Customization Options: Different industries require specific sizes, colors, textures, and finishes. A reliable supplier should offer customization services, allowing businesses to obtain PET sheets that match their exact requirements.

Delivery Times and Flexibility: Quick turnaround times and a flexible supply chain are important when sourcing PET sheets. Suppliers should be able to handle bulk orders and provide timely delivery, especially when businesses have strict production timelines.

Sustainability: As sustainability becomes a growing concern for many industries, PET sheet suppliers should be able to offer environmentally friendly options, including recycled PET (rPET) sheets, to meet the demand for greener alternatives.

Cost-effectiveness: While PET sheets are relatively affordable, price variation can exist depending on factors such as quality, customization, and order size. Suppliers should offer competitive pricing and cost transparency.

The Future of PET Sheet Supply

The future of the PET sheet market looks promising, as industries continue to seek cost-effective, sustainable, and high-performance materials. With the increasing demand for eco-friendly solutions, the role of PET sheet suppliers in providing recycled or bio-based PET is becoming more important. Innovations in manufacturing processes are also expected to improve the material’s properties, such as enhancing its resistance to extreme conditions, expanding its potential applications.

Furthermore, as the global market for consumer electronics, packaging, and construction continues to grow, the need for high-quality PET sheets is expected to rise, creating opportunities for suppliers to meet the evolving needs of businesses.

In conclusion, PET sheet suppliers play a crucial role in providing a material that is not only functional but also environmentally responsible. As industries seek more sustainable and versatile solutions, the demand for PET sheets is likely to continue expanding, driven by the material’s durability, recyclability, and cost-effectiveness.