In the fast-paced world of industrial manufacturing, efficiency and precision are paramount. Whether you're working with metal, concrete, or other materials, the need for a cleaning solution that is both effective and environmentally friendly has never been more critical. Enter industrial laser cleaner – a revolutionary technology that has transformed the way industries handle surface cleaning. In this blog, we’ll explore how laser cleaning works, its benefits, and why your business should consider integrating it into your operations.

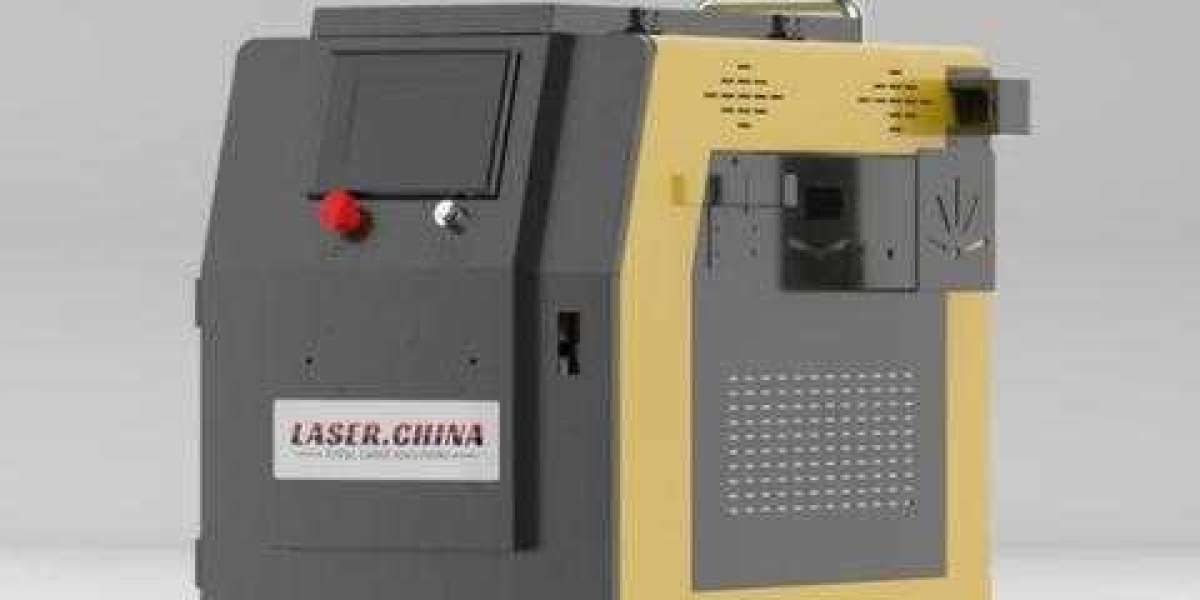

What is an Industrial Laser Cleaner? An industrial laser cleaner is a cutting-edge technology designed to remove contaminants from the surfaces of materials like metals, plastics, ceramics, and even concrete. Using high-powered laser beams, it targets the unwanted particles, such as rust, paint, oil, and dirt, effectively vaporizing them without damaging the underlying material.

Laser cleaning offers a high degree of precision compared to traditional methods such as sandblasting or chemical cleaning. The laser beam removes contaminants at a microscopic level, ensuring a smooth and clean surface, ideal for subsequent processes like coating or welding.

How Does Industrial Laser Cleaning Work? Industrial laser cleaning relies on focused laser energy to remove surface contaminants. The process works by directing a laser beam onto the material's surface, causing the unwanted particles to absorb the energy and either evaporate or be blown away by a gas flow. The laser can be adjusted for different materials, allowing it to clean surfaces of various types and compositions without causing any damage to the substrate.

The system is often computer-controlled, ensuring precise cleaning and minimal waste. In addition, the process is contactless, meaning there is no physical wear on the surface or the equipment, extending the lifespan of both the workpiece and the cleaning machinery.

Key Benefits of Using Industrial Laser Cleaners:

Eco-Friendly and Safe: Unlike traditional cleaning methods that involve harsh chemicals or abrasive materials, laser cleaning is a green solution. It doesn’t require chemical agents, making it safe for the environment and workers. Additionally, there is no waste generated from the process, reducing the overall ecological impact.

Non-Destructive and Precise: Industrial laser cleaners are incredibly precise, ensuring that only the contaminants are removed without affecting the underlying material. Whether cleaning a delicate metal surface or a large industrial piece, the laser can be adjusted to suit the specific requirements of the job, providing a level of control and precision not achievable with manual or abrasive cleaning methods.

Cost-Effective: Although the initial investment in laser cleaning equipment may seem high, the long-term savings are substantial. Traditional cleaning methods often require repeated use of chemicals, abrasives, or labor, all of which add to the cost. Laser cleaning requires less maintenance and fewer consumables, providing a lower total cost of ownership over time.

Increased Productivity: The speed of laser cleaning is another key advantage. The process is faster than manual cleaning methods and doesn’t require any downtime between cycles. As a result, industrial laser cleaners can significantly increase productivity, allowing companies to complete more cleaning tasks in less time.

Versatility: One of the most remarkable features of industrial laser cleaners is their versatility. They can be used for a wide range of applications, from removing rust on metal parts to preparing surfaces for coating. Industries such as automotive, aerospace, electronics, and manufacturing all benefit from the adaptability of laser cleaning technology.

Minimal Wear and Tear: Because the laser cleaning process is non-contact, there’s minimal wear and tear on the equipment and the material being cleaned. This results in reduced maintenance costs and a longer lifespan for both your machinery and workpieces.

Applications of Industrial Laser Cleaning: Laser cleaning is used across various industries, providing solutions for a range of needs:

- Rust and Paint Removal: Laser cleaners are ideal for removing rust, coatings, and paint from metal surfaces without damaging the base material.

- Welding and Surface Preparation: Prior to welding or coating, laser cleaning can prepare the surface to ensure stronger bonds and better finishes.

- Precision Cleaning: In high-precision industries like electronics or aerospace, laser cleaning ensures surfaces are free from contaminants without affecting fine tolerances.

Conclusion: As industries continue to look for ways to enhance productivity while reducing environmental impact, Industrial laser cleaner stands out as an advanced solution. Whether you're in manufacturing, aerospace, or automotive, laser cleaners offer unparalleled precision, efficiency, and sustainability. Make the shift to laser cleaning and take advantage of the numerous benefits it brings to your operations.