In the modern world of manufacturing and industrial operations, the need for efficient, eco-friendly, and precise cleaning solutions is greater than ever. Traditional cleaning methods, such as abrasive blasting or chemical treatments, often pose environmental hazards, require high labor costs, and can lead to material damage. Enter industrial laser cleaner, a groundbreaking technology that is transforming the way we approach industrial surface cleaning. This blog delves into the many advantages of laser cleaning technology, its application, and why it's becoming a game-changer in various industries.

What is an Industrial Laser Cleaner?

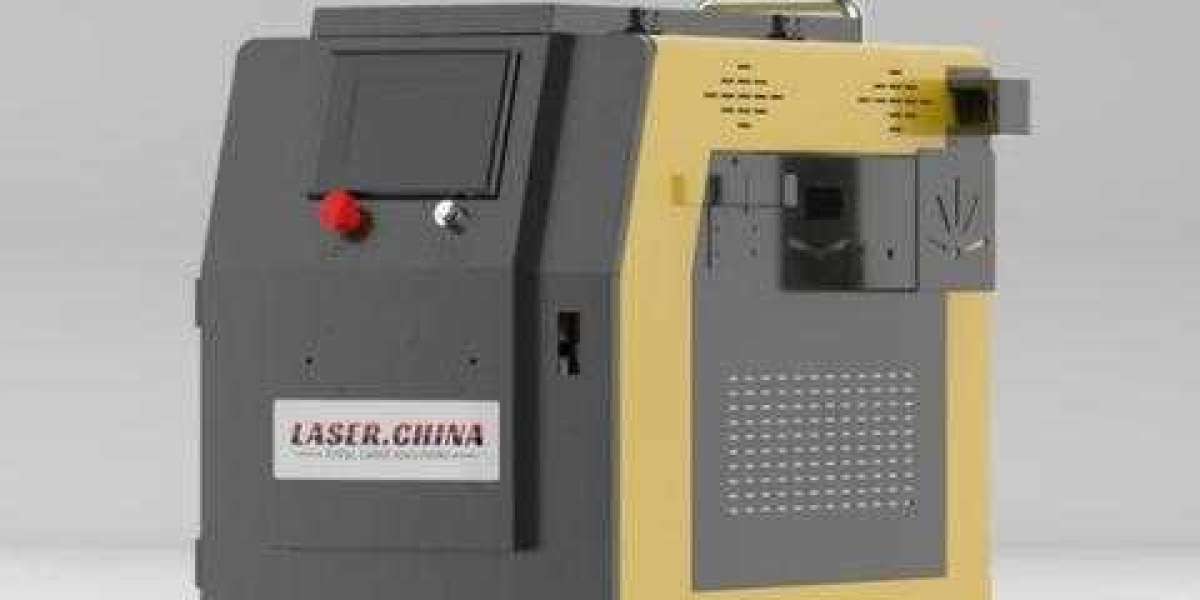

An industrial laser cleaner is a state-of-the-art tool that uses high-intensity laser beams to remove contaminants, rust, paint, coatings, and other impurities from the surface of materials without causing any damage. It works by focusing concentrated light onto the surface, where the high heat vaporizes or ejects the unwanted substances, leaving the material underneath pristine and untouched.

Unlike traditional methods that rely on abrasives or toxic chemicals, laser cleaning is non-abrasive, reducing the risk of damage to delicate surfaces, while also being environmentally friendly. The technology is suitable for a wide range of materials including metals, plastics, ceramics, and composites, making it highly versatile for industrial applications.

Why Choose Laser Cleaning Over Traditional Methods?

1. Eco-Friendly and Sustainable

One of the primary benefits of industrial laser cleaners is their minimal environmental impact. Traditional cleaning methods often involve harsh chemicals, solvents, or abrasive materials that can harm the environment. In contrast, laser cleaning uses only the power of light, which makes it a more sustainable and cleaner option. No toxic waste or chemicals are produced during the cleaning process, making it an ideal choice for industries looking to minimize their carbon footprint.

2. Precision and Efficiency

Laser cleaning offers unmatched precision. The laser can be finely tuned to clean specific areas without affecting the surrounding material. This precision makes laser cleaners especially valuable in industries where delicate parts and fine surfaces are prevalent. Whether it's cleaning rust from intricate machinery or removing paint from a sensitive surface, laser technology provides a level of accuracy that cannot be achieved with traditional methods.

Moreover, laser cleaning is significantly faster. The high-powered lasers can cover large surface areas in a short period, improving operational efficiency. This not only reduces downtime but also increases productivity, as the cleaning process can be automated for continuous operations.

3. Cost-Effective in the Long Run

While the initial investment in an industrial laser cleaner may be higher compared to traditional cleaning systems, the long-term savings are substantial. Laser cleaners require minimal maintenance, have fewer consumables, and reduce the need for manual labor, which translates to reduced operational costs. Furthermore, the laser cleaning process is highly durable, making it a reliable long-term solution.

4. Reduced Material Damage

Unlike abrasive cleaning methods, laser cleaning doesn’t involve physical contact with the surface, reducing the likelihood of wear and tear on parts. Abrasive materials can cause micro-abrasions, potentially compromising the integrity of a surface over time. By eliminating this risk, laser cleaning helps prolong the lifespan of expensive machinery and materials.

5. Versatile Applications

The industrial laser cleaner can be used across a wide range of industries, including automotive, aerospace, metalworking, electronics, and more. Some common applications include:

- Rust Removal: Laser cleaning is highly effective in removing rust from metal surfaces, helping to restore parts to their original state without causing any damage.

- Coating Removal: Laser technology is also adept at removing paint, coatings, and adhesives, making it suitable for refurbishing old components.

- Surface Preparation: The laser can prepare metal surfaces for welding or coating by removing oxides and contaminants that would otherwise interfere with adhesion.

- Decarbonizing Engine Parts: Laser cleaning can be used to remove carbon build-up from engine parts, which can improve performance and extend the life of machinery.

Key Features of Laser Cleaning Technology

- Adjustable Power Settings: Laser cleaners offer customizable power levels to suit different cleaning tasks. Whether you're working with delicate electronics or large machinery, the power of the laser can be adjusted to meet the specific needs of the job.

- Remote Operation and Automation: Many modern laser cleaners can be operated remotely, enhancing safety and ease of use. Automation capabilities allow for continuous cleaning, minimizing the need for manual intervention and further improving efficiency.

- Compact and Portable Design: Laser cleaning systems are often designed to be compact and portable, allowing them to be easily moved around large facilities or applied to different workstations.

- Minimal Maintenance: With fewer moving parts compared to traditional cleaning systems, laser cleaners require less maintenance, leading to lower downtime and repair costs.

The Future of Industrial Laser Cleaning

As industries continue to embrace more sustainable and efficient technologies, laser cleaning is poised to become a cornerstone of industrial surface preparation. With advancements in laser technology, we can expect even more precise and powerful systems in the future, capable of cleaning a broader range of materials and contaminants. As the demand for cleaner, faster, and more cost-effective industrial cleaning solutions grows, laser cleaning will undoubtedly play an essential role in shaping the future of manufacturing.

Conclusion

Industrial laser cleaner offer a revolutionary approach to cleaning and surface preparation, combining efficiency, sustainability, and precision. With a wide array of applications across multiple industries, laser cleaning is set to become the preferred choice for businesses looking to enhance their cleaning processes while reducing their environmental impact. Whether you're in the automotive, aerospace, or manufacturing sectors, adopting laser cleaning technology can provide significant long-term benefits and elevate your operations to new heights.