Whether it’s for road construction, railway embankments, or foundation stabilization, it’s essential to have a reliable solution that prevents soil movement, erosion, and settlement. One such innovation in the field of geotechnical engineering is the uniaxial geogrid. The application of uniaxial geogrids has revolutionized ground stabilization processes, offering both cost-effective and efficient solutions. In this article, we will explore the power of Uniaxial geogrid exporters in Ahmedabad, their applications, benefits, and why they have become a crucial tool for modern construction.

What is a Uniaxial Geogrid?

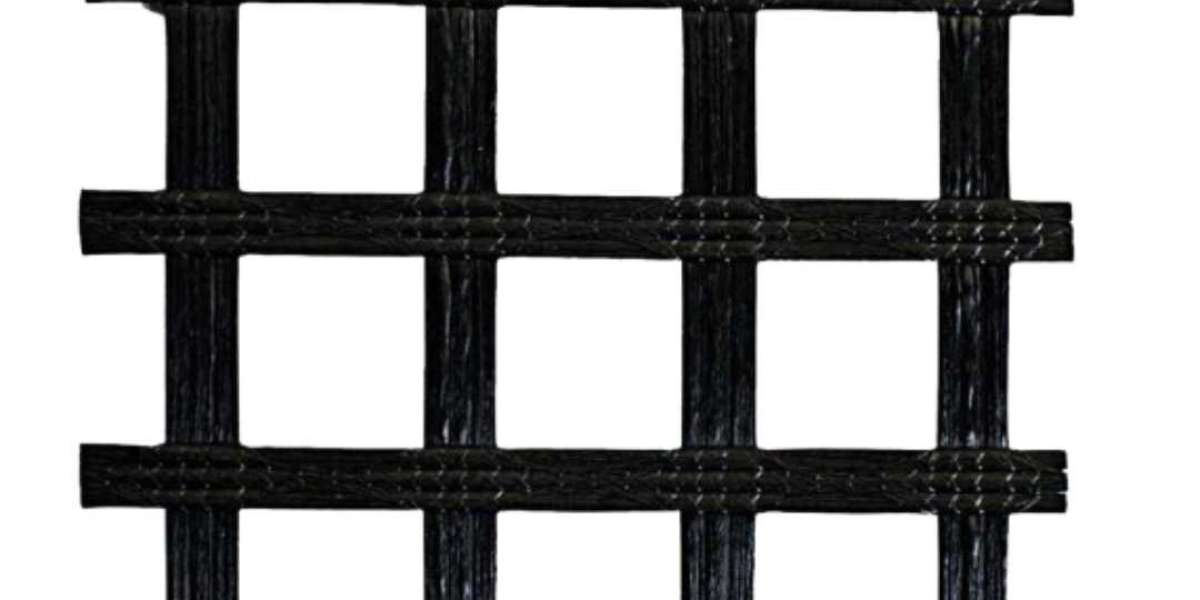

A uniaxial geogrid is a high-performance geosynthetic material made of polymeric substances such as polypropylene or polyester. These grids are designed with longitudinal ribs and apertures to provide stability to the soil by allowing it to interlock with the material. The primary feature of uniaxial geogrids is their ability to resist tension in one direction, which makes them especially effective in applications where tensile forces are primarily acting in a single direction, such as in slopes or embankments.

The manufacturing process of uniaxial geogrids involves stretching the polymeric material in one direction to form a grid structure that can handle tensile loads. The structure of these geogrids enhances soil reinforcement by providing mechanical interlock with the soil particles, offering significant stability.

The Role of Uniaxial Geogrids in Ground Stabilization

Ground stabilization is crucial for maintaining the integrity of construction projects, especially in areas where the soil is loose, weak, or prone to shifting. Uniaxial geogrids help in improving the strength and stability of soils, preventing issues like erosion, shifting, and failure. Below are some specific applications where uniaxial geogrids make a substantial impact:

1. Road Construction

Roads constructed on weak soil or on soft subgrade often face issues like rutting and settling. By incorporating uniaxial geogrids into the base layers, engineers can create a more stable foundation. The geogrid helps distribute the load and prevent differential settlement, which ultimately extends the life of the road and reduces maintenance costs.

2. Railway Embankments

Uniaxial geogrids are widely used in the construction of railway embankments to prevent soil deformation under heavy loads. The load distribution properties of uniaxial geogrids help in minimizing differential settlement, thus ensuring the stability of the tracks.

3. Slope Stabilization

In areas with steep slopes, the soil can be prone to slippage and erosion. Uniaxial geogrids act as a support structure, holding the soil in place and preventing soil movement. This function is critical in regions that are prone to landslides or erosion due to rain or other environmental factors.

4. Retaining Walls

In the construction of retaining walls, uniaxial geogrids are used to reinforce the soil behind the wall, providing additional strength and preventing the wall from failing under lateral pressures. The grid structure of the geogrid helps distribute forces, ensuring that the retaining wall maintains its structural integrity.

Benefits of Uniaxial Geogrids

The widespread use of Uniaxial geogrid manufacturers in Ahmedabad in various construction projects is not without reason. These geosynthetics offer several benefits, making them a popular choice among engineers and construction firms. Some of the key benefits include:

1. Enhanced Load Distribution

Uniaxial geogrids improve the load distribution of the ground, allowing construction materials to spread the weight evenly. This prevents the formation of weak points in the soil, which could lead to settlement, rutting, or even failure of the structure.

2. Improved Soil Reinforcement

Geogrids act as a reinforcement material, increasing the tensile strength of the soil and making it more capable of withstanding heavy loads. The soil particles interlock with the geogrid, creating a stronger matrix that enhances the overall stability of the ground.

3. Cost-Efficiency

Using uniaxial geogrids can significantly reduce the need for expensive soil improvements, such as soil compaction or the use of larger amounts of concrete and other materials. Their cost-effectiveness makes them an attractive option for construction companies looking to reduce project expenses while ensuring safety and quality.

4. Sustainability

Geogrids are made from polymers that are durable, weather-resistant, and can last for decades without degradation. This longevity ensures that maintenance costs are minimal, and it helps in reducing the carbon footprint of construction projects. Furthermore, their use reduces the need for more environmentally harmful alternatives, such as large quantities of stone or concrete.

UNIAXIAL GEOGRID EXPORTERS AND MANUFACTURERS IN AHMEDABAD, INDIA

Ahmedabad, a major hub of industrial activity in India, is home to numerous uniaxial geogrid exporters and manufacturers who have played an important role in the growing demand for ground stabilization materials. The city’s geogrid manufacturing sector has grown rapidly, providing high-quality products to domestic and international markets. Uniaxial geogrid exporters in Ahmedabad are well-regarded for their ability to supply customized products that meet the specific needs of different industries, ensuring that each project receives the ideal solution for optimal performance.

Uniaxial geogrid manufacturers in Ahmedabad focus on creating geogrids that are strong, durable, and capable of handling varying soil conditions. The expertise of these manufacturers, along with advanced technology and materials, ensures that the geogrids are suited for a range of applications, from road construction to slope stabilization.

Moreover, Uniaxial geogrid exporters in India are helping expand the international footprint of this product. As countries around the world invest in infrastructure development, the demand for high-quality ground stabilization materials is growing. Indian manufacturers are meeting this need by exporting advanced uniaxial geogrids to countries across continents, ensuring that the benefits of this technology are accessible worldwide.

Conclusion

The role of uniaxial geogrids in ground stabilization has proven to be invaluable for modern construction practices. By improving load distribution, reinforcing soil, and offering cost-effective and sustainable solutions, uniaxial geogrids are at the forefront of addressing the challenges of ground stability. With the help of uniaxial geogrid exporters and manufacturers in Ahmedabad, India, this powerful geosynthetic material is now accessible to a global market, revolutionizing construction projects across industries.

As infrastructure development continues to grow, the demand for high-quality, efficient, and durable ground stabilization solutions will only increase. Uniaxial geogrids, with their innovative design and proven benefits, will continue to play an essential role in shaping the future of construction.

Frequently Asked Questions

How do uniaxial geogrids contribute to ground stabilization?

Uniaxial geogrids contribute to ground stabilization by providing tensile strength in one direction, improving load distribution and soil reinforcement. They prevent soil movement, reduce settlement, and help in preventing erosion, making them ideal for road construction, slope stabilization, and railway embankments.

Can uniaxial geogrids be used in all types of soil conditions?

Yes, uniaxial geogrids are versatile and can be used in various soil conditions, including soft, weak, or unstable soils. Their ability to reinforce the soil and distribute loads effectively makes them suitable for challenging environments, ensuring long-term stability.

What are the advantages of using uniaxial geogrids over traditional ground stabilization methods?

The key advantages of uniaxial geogrids over traditional methods include their cost-effectiveness, ease of installation, long-lasting durability, and environmental sustainability. Unlike traditional methods, which may require extensive soil treatment or additional material, geogrids provide an efficient and reliable solution that reduces long-term maintenance costs.