However, the need for durable, cost-effective, and sustainable construction materials has never been greater. In recent years, polyester geogrids have emerged as a revolutionary solution in the field of geotechnical engineering. These high-performance materials have reshaped the way we approach construction and infrastructure projects, offering unmatched strength, flexibility, and reliability. Let’s delve into the versatility and strength of PP geogrid manufacturer in Indiaand explore how they are transforming the landscape of modern infrastructure development.

What Are Polyester Geogrids?

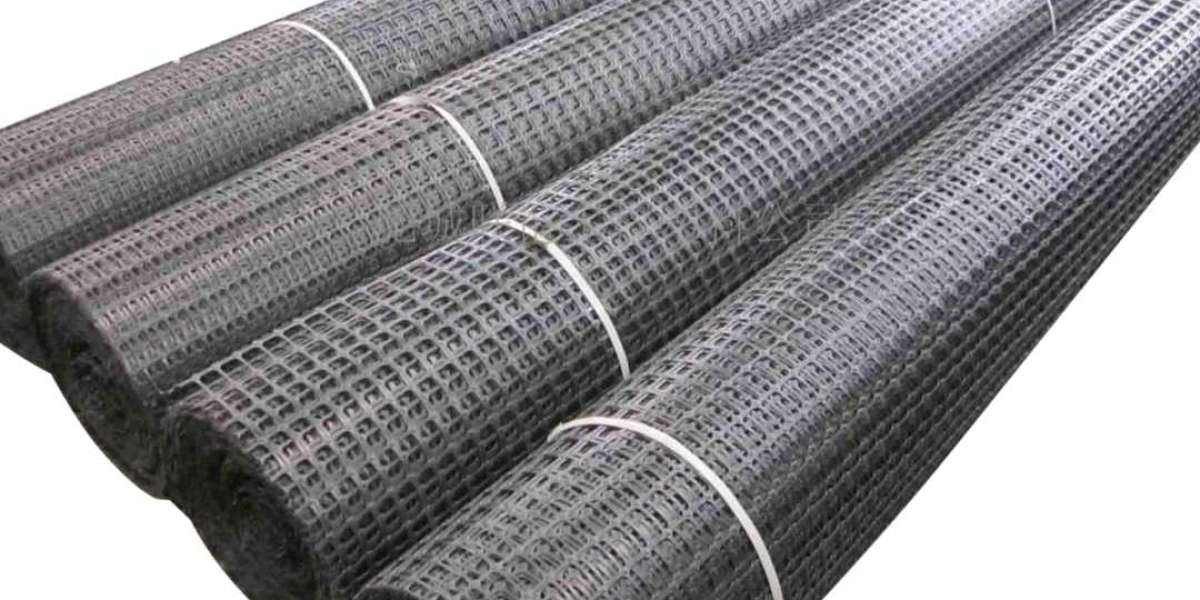

Polyester geogrids are advanced geosynthetic materials designed to reinforce soil, aggregate, and other construction materials. They are made from high-tenacity polyester yarns that are coated with polymer to enhance durability and resistance to environmental factors. Polyester geogrids are widely used in applications such as road construction, railway stabilization, retaining walls, and embankments.

The primary role of polyester geogrids is to improve the mechanical properties of the soil by distributing loads evenly and minimizing deformation. They are particularly effective in areas with challenging soil conditions, such as weak or unstable subgrades, where traditional materials might fail.

Key Benefits of Polyester Geogrids

- Superior Tensile Strength: Polyester geogrids offer exceptional tensile strength, making them ideal for reinforcing soil in demanding applications. Their strength helps reduce the risk of cracking and settlement, ensuring long-term stability.

- High Durability: These geogrids are resistant to UV radiation, chemicals, and biological degradation, ensuring they perform well in harsh environments. This durability extends the lifespan of infrastructure projects, reducing maintenance costs.

- Cost-Effectiveness: By enhancing soil performance, polyester geogrids minimize the need for expensive excavation and replacement of weak soils. This results in significant cost savings during construction.

- Environmental Sustainability: Polyester geogrids reduce the amount of raw materials required in construction, making projects more eco-friendly. Their lightweight design also lowers transportation emissions.

- Ease of Installation: Lightweight and flexible, polyester geogrids are easy to transport and install, saving time and labor on-site. They can be cut and customized to fit specific project requirements.

Applications of Polyester Geogrids

Polyester geogrids have a broad range of applications, making them indispensable in modern infrastructure development. Some of the most common uses include:

1. Road Construction

One of the primary applications of polyester geogrids is in road construction. By reinforcing the subgrade, these geogrids prevent rutting and cracking, extending the lifespan of roads. They also enhance load distribution, reducing the risk of structural failure.

2. Railway Stabilization

In railway construction, polyester geogrids stabilize the track bed, ensuring smooth and safe operations. They minimize track settlement and improve load-bearing capacity, making them a preferred choice for railway engineers.

3. Retaining Walls and Slopes

Polyester geogrids are widely used in the construction of retaining walls and steep slopes. Their tensile strength and flexibility allow for the construction of stable, space-efficient structures in challenging terrains.

4. Embankments on Weak Soils

When constructing embankments over weak or compressible soils, polyester geogrids provide the necessary reinforcement to prevent settlement and instability. They enable the construction of embankments with reduced material requirements, saving costs and time.

5. Erosion Control

In areas prone to erosion, polyester geogrids help stabilize the soil and prevent surface degradation. They are commonly used in riverbanks, coastal areas, and slopes to maintain soil integrity and reduce erosion.

The Role of Local Manufacturers and Suppliers

The production and supply of polyester geogrids play a crucial role in ensuring the success of infrastructure projects. Local manufacturers and suppliers, such as pp geogrid manufacturer in India, contribute significantly to meeting the growing demand for high-quality geosynthetic materials. They offer customized solutions tailored to the specific needs of projects, ensuring optimal performance and reliability.

In Ahmedabad, a hub of industrial activity, PP geogrid supplier in Ahmedabadis well-positioned to provide advanced geogrid products to various sectors. Their expertise and commitment to quality have made them a trusted partner for contractors and engineers across the region.

Similarly, pp geogrid manufacturer in Gujarat has established itself as a leader in the production of polyester geogrids. By leveraging state-of-the-art technology and adhering to stringent quality standards, these manufacturers ensure their products meet the rigorous demands of modern infrastructure projects.

Advancements in Polyester Geogrid Technology

Continuous innovation in the field of geosynthetics has led to significant advancements in polyester geogrid technology. Some notable developments include:

- Enhanced Coatings: New polymer coatings improve resistance to environmental factors, such as moisture and chemicals, further extending the lifespan of geogrids.

- Eco-Friendly Materials: Manufacturers are developing geogrids made from recycled materials, contributing to sustainability efforts in the construction industry.

- Custom Designs: Advances in manufacturing techniques allow for the production of geogrids with customized specifications, catering to unique project requirements.

These innovations have expanded the potential applications of polyester geogrids, making them a versatile solution for diverse infrastructure challenges.

Conclusion

Polyester geogrids have revolutionized the construction and infrastructure industries by offering a reliable, cost-effective, and sustainable solution for soil reinforcement. Their versatility, durability, and superior performance make them indispensable in applications ranging from road construction to erosion control. With the support of local manufacturers and suppliers, such as pp geogrid manufacturer in India, pp geogrid supplier in Ahmedabad, and PP geogrid manufacturer in Gujaratthe adoption of polyester geogrids is set to grow exponentially in the coming years.

As infrastructure development continues to accelerate, polyester geogrids will remain at the forefront of innovation, ensuring projects are built to last while minimizing environmental impact. By embracing this cutting-edge technology, we can create a more resilient and sustainable future.

Frequently Asked Questions (FAQs)

1. What are the key features of polyester geogrids?

Polyester geogrids are known for their high tensile strength, durability, and resistance to environmental factors such as UV radiation and chemicals. They are lightweight, easy to install, and suitable for a wide range of applications, including road construction and slope stabilization.

2. How do polyester geogrids contribute to cost savings in construction projects?

Polyester geogrids enhance soil performance, reducing the need for excavation and replacement of weak soils. They also minimize maintenance costs by improving the durability and lifespan of infrastructure projects.

3. Why should I choose a local manufacturer or supplier for polyester geogrids?

Local manufacturers and suppliers, such as pp geogrid manufacturer in Gujarat or pp geogrid supplier in Ahmedabad, provide customized solutions and faster delivery times. Their proximity ensures better support and quality assurance for your project needs.