In the competitive jewelry industry, precision and quality are key factors in crafting exquisite designs. Jewellery manufacturing solutions provide businesses with the tools and technology necessary to enhance production efficiency, improve accuracy, and maintain consistency in their creations. From advanced casting techniques to laser engraving and high-precision weighing scales, these solutions streamline the manufacturing process while ensuring superior craftsmanship. Here are some essential factors to consider when investing in jewellery manufacturing equipment.

Advanced Casting and Molding Techniques

Casting is a crucial step in jewellery manufacturing that determines the final shape and structure of the product. Modern jewellery manufacturing solutions offer advanced casting techniques such as vacuum casting, lost wax casting, and centrifugal casting, which ensure high-quality results with minimal defects. These methods help jewelers create intricate designs with precise detailing, reducing material wastage and improving overall production efficiency.

Precision Cutting and Engraving with Laser Technology

Laser technology has revolutionized the jewellery industry, offering precise cutting and engraving solutions. Laser cutting machines enable jewelers to create complex patterns and detailed engravings with high accuracy, making them ideal for customization and branding. Additionally, laser welding allows seamless joining of metal components without excessive heat, preserving the integrity of delicate jewellery pieces. Investing in laser technology enhances production speed while maintaining exceptional craftsmanship.

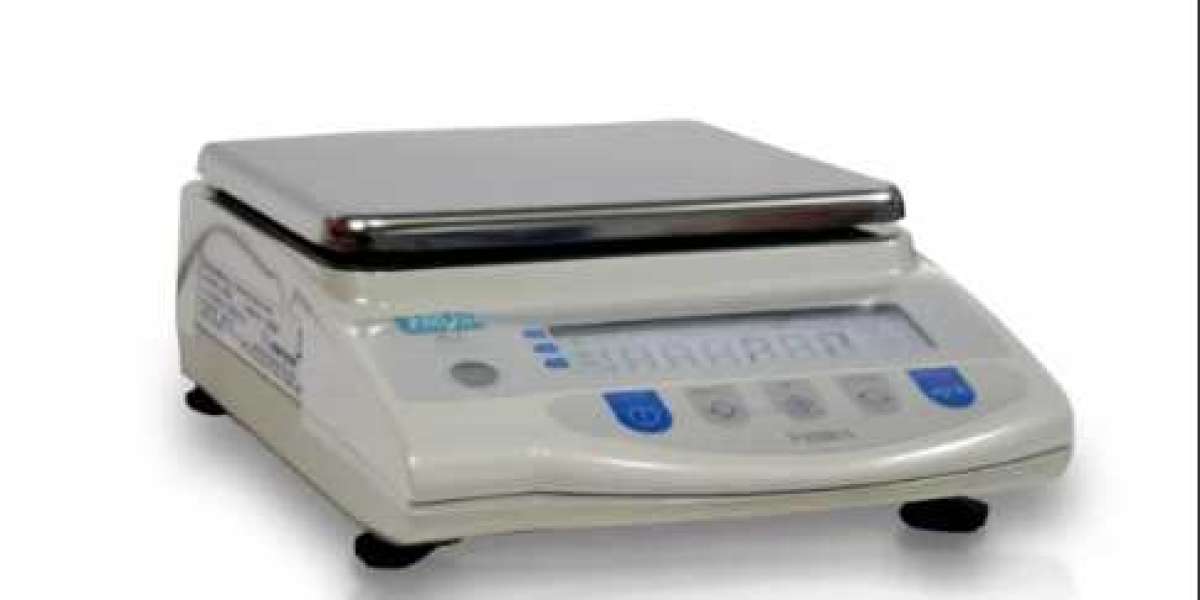

High-Precision Weighing Scales for Accurate Measurements

Accurate weight measurement is essential in jewellery manufacturing, as even minor variations can impact the quality and value of the final product. High-precision weighing scales help jewelers measure gold, silver, and gemstones with utmost accuracy. Digital scales with advanced sensors provide quick and precise readings, ensuring compliance with industry standards. These weighing solutions play a vital role in maintaining consistency and transparency in jewellery production.

Quality Control and Gold Purity Testing Machines

Ensuring the purity of gold and other precious metals is critical in jewellery manufacturing. Gold testing machines, such as X-ray fluorescence (XRF) analyzers, provide non-destructive and highly accurate purity assessments. These machines help manufacturers maintain quality assurance, meet regulatory standards, and build customer trust. By integrating reliable gold purity analyzers into their production process, jewellery manufacturers can enhance product authenticity and avoid impurities in their materials.

Automation and Smart Manufacturing Solutions

The adoption of automation in jewellery manufacturing has significantly improved efficiency and productivity. Automated polishing machines, CNC milling systems, and 3D printing technology allow manufacturers to produce jewellery with greater precision and reduced manual effort. Smart manufacturing solutions also enable real-time monitoring of production processes, ensuring high-quality output with minimal errors. Investing in automation enhances scalability and reduces production costs over time.

Conclusion

Incorporating advanced jewellery manufacturing solutions into your production process is essential for achieving precision, efficiency, and quality. From modern casting techniques and laser engraving to high-precision weighing scales and automated manufacturing, these technologies enhance productivity while maintaining superior craftsmanship. By investing in reliable jewellery manufacturing equipment, businesses can stay ahead in the competitive market and deliver exceptional products that meet industry standards and customer expectations.