Instrumentation valves play a crucial role in controlling and regulating fluid flow in various industrial applications. These valves are essential in industries such as oil and gas, chemical processing, power plants, and manufacturing. They ensure the safe and efficient operation of valves and instruments, providing reliability and precision in fluid handling systems. In this blog, we will explore different types of instrumentation valves, their functions, and their applications.

What Are Instrumentation Valves?

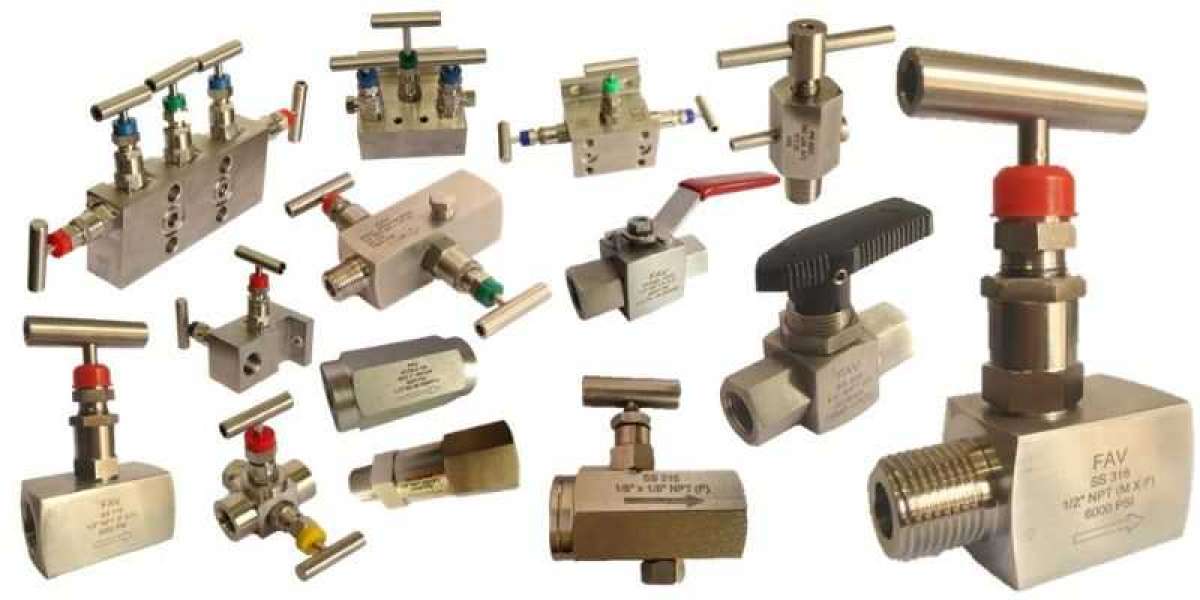

Instrumentation valves are specially designed to control fluid flow, pressure, and temperature in process systems. They provide precise regulation, isolation, and measurement in critical industrial environments. These valves are widely used in pipelines, hydraulic systems, and instrumentation panels to ensure accurate monitoring and safety.

Types of Instrumentation Valves

Needle Valves

Needle valves are commonly used for precise flow control and pressure regulation. These valves feature a small, tapered needle-like plunger that fits into a matching seat to regulate fluid flow. Needle valves are ideal for applications requiring fine adjustments and leak-proof sealing, such as gas chromatography, pressure testing, and hydraulic systems.

Ball Valves

Ball valves are highly efficient in providing quick shut-off and control of fluid flow. They use a rotating ball with a bore to allow or restrict flow. Ball valve manufacturers offer various types, including full-port and reduced-port ball valves, for different industrial needs. These valves are used in oil and gas, chemical processing, and power generation plants due to their durability and leak-proof operation.

Check Valves

Check valves are unidirectional valves designed to prevent backflow in a pipeline. These valves operate automatically and do not require manual control. Check valve manufacturers produce different types of check valves, such as swing check valves, lift check valves, and diaphragm check valves. They are widely used in water treatment, HVAC systems, and industrial process control.

Manifold Valves in Instrumentation

Manifold valves are specialized assemblies designed for use with pressure and differential pressure instruments. They combine multiple valves into a single unit, reducing the number of connections and potential leak points.

- 2 Valve Manifold

2 valve manifold consists of one isolation valve and one equalizing valve. These manifolds are used in static pressure and liquid level applications to isolate the pressure transmitter from the process and equalize the pressure.

- 3 Valve Manifold

3 valve manifold consists of two isolation valves and one equalizing valve. These are commonly used in differential pressure transmitters to balance the pressure before taking measurements.

- 5 Valve Manifold

5 valve manifold consists of two isolation valves, one equalizing valve, and two vent valves. These are used in complex differential pressure applications, offering additional control and flexibility.

Conclusion

Instrumentation valves play a crucial role in industrial automation and process control. Whether using needle valves, ball valves, or check valves, selecting the right type ensures accuracy, safety, and efficiency in operations. Leading ball valve manufacturers and check valve manufacturers provide high-quality solutions for various industries. Understanding Avlok 2-valve manifold, 3-valve manifold, and 5-valve manifold systems can help industries optimize performance and reliability in fluid control applications.