In today’s construction industry, efficiency, precision, and adaptability are the cornerstones of successful production lines. As building demand continues to grow globally, brick manufacturers are constantly looking for ways to streamline operations, reduce waste, and produce high-quality bricks more efficiently. Enter the Compact Vacuum Extruder — a machine that has become a game changer, especially for small to medium-sized brick factories.

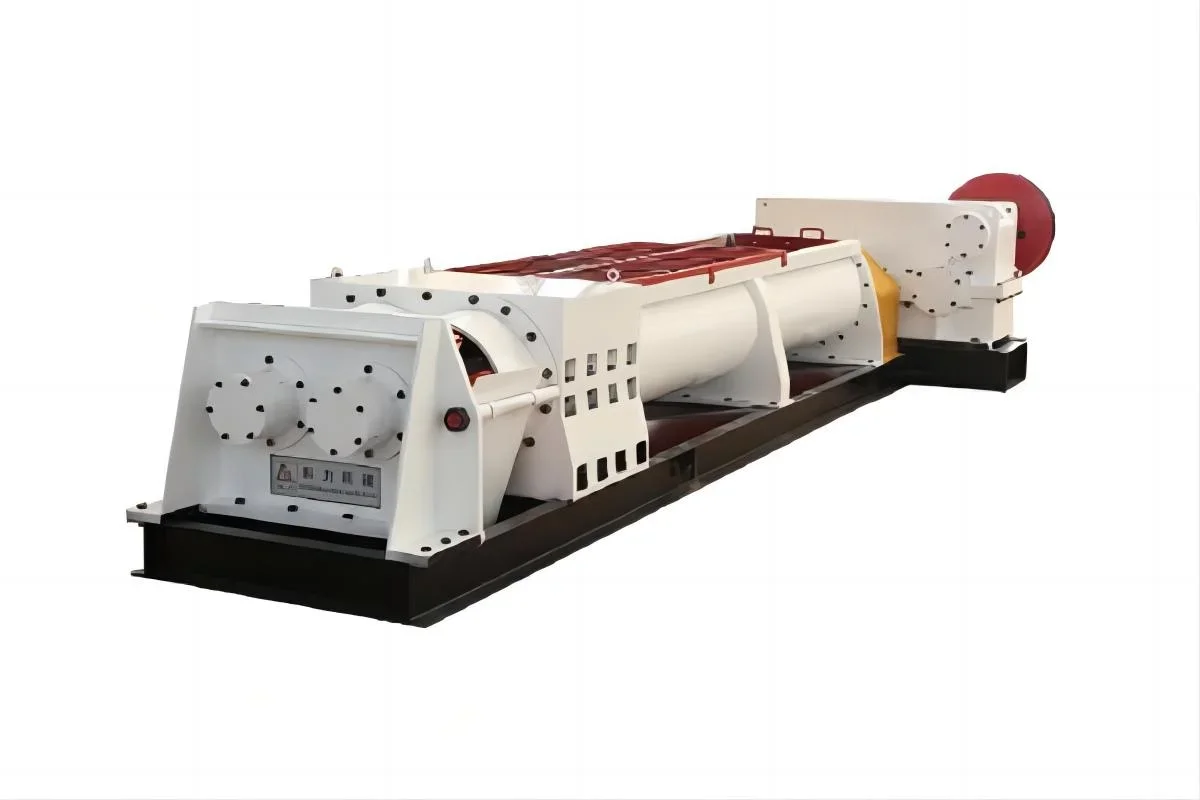

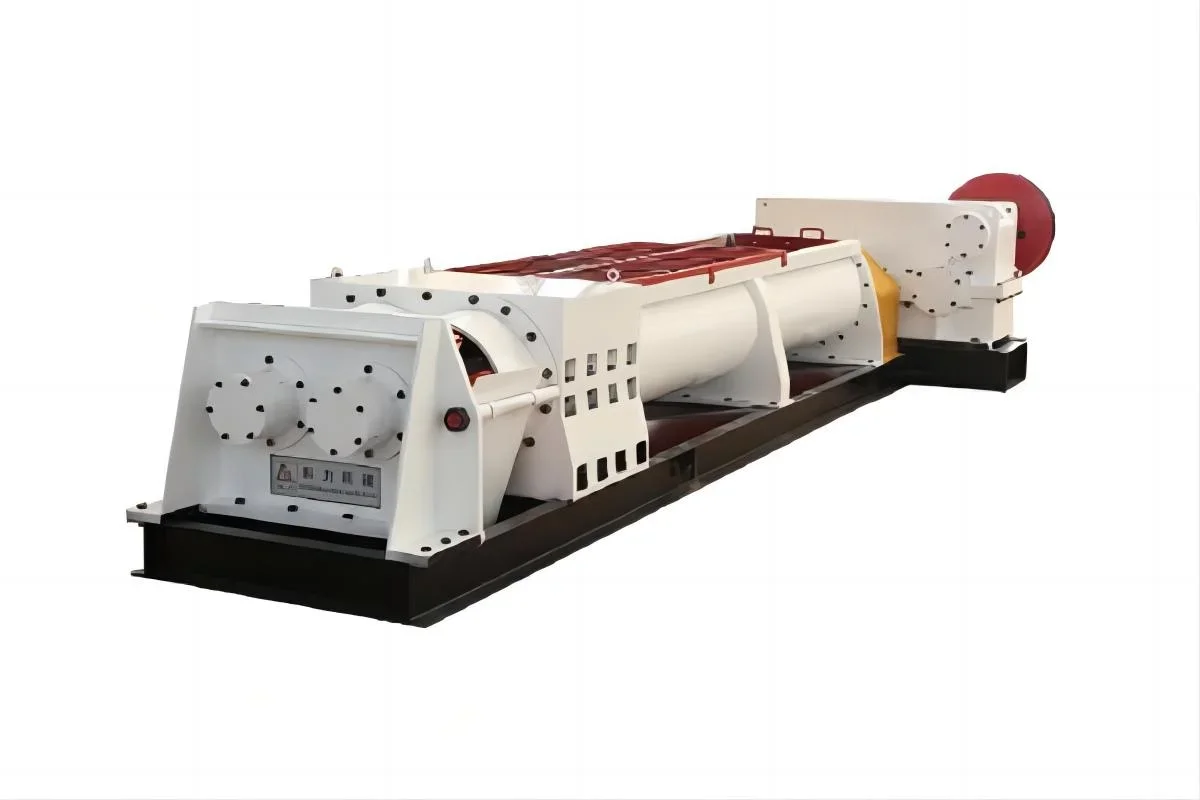

Among the leading names in this technology is KeLi Machine, a trusted manufacturer of innovative construction machinery. KeLi’s compact vacuum extruder stands out as a reliable, space-saving, and high-performance solution for modern brick-making needs.

What Is a Compact Vacuum Extruder?

A vacuum extruder is a core piece of equipment in clay brick and tile production. It works by de-airing and compressing clay before forcing it through a mold to create bricks or other shapes. The compact version of this machine retains all the key functions of a full-sized extruder but is specifically designed to:

1. Save floor space

2. Reduce energy consumption

3. Enable easier installation and maintenance

4. Lower overall operating costs

It is especially ideal for small-scale brick manufacturers, mobile plants, or those with limited workshop space.

KeLi Machine: Setting the Standard in Compact Extrusion

At KeLi Machine, innovation and reliability go hand in hand. As a leading manufacturer and supplier of advanced construction machinery, we are committed to providing state-of-the-art solutions that help our clients maximize productivity while minimizing operational challenges.

Our compact vacuum extruders are designed with:

1. Robust engineering for long-term performance

2. Smart vacuum technology for optimal de-airing and shaping

3. User-friendly controls to simplify operation

4. Customizable configurations for different clay types and outputs

Every unit undergoes strict quality checks, ensuring it meets both international standards and practical demands on the factory floor.

Key Features of the KeLi Compact Vacuum Extruder

Let’s take a closer look at what makes our https://www.yxkelijixie.com/Compact-vacuum-extruder.html stand out:

1. Efficient De-Airing System

A high-performance vacuum chamber ensures that air bubbles are removed from the clay mixture before shaping. This results in bricks that are:

Structurally stronger

More resistant to cracking and shrinkage

Consistently dense and uniform

2. Compact and Modular Design

The space-saving structure makes the machine ideal for both fixed and mobile production sites. It integrates seamlessly into existing production lines without major adjustments.

3. Durable Components

From the mixing blades to the wear-resistant extrusion die, every part is made from high-grade materials that ensure durability and reduce downtime.

4. Energy-Efficient Motor System

Equipped with advanced motors and transmission systems, our compact vacuum extruder minimizes power usage while maintaining a high output rate.

5. Custom Output Configurations

Whether you need solid bricks, hollow bricks, or special formats, the machine can be adjusted with different molds and dies to meet your requirements.

Benefits for Brick Manufacturers

By investing in the KeLi Compact Vacuum Extruder, brick manufacturers unlock a range of benefits that impact their bottom line and production efficiency.

1. Higher Brick Quality

The vacuum extrusion process produces smoother, denser, and more uniform bricks — increasing both customer satisfaction and structural reliability in end-use construction.

2. Lower Production Costs

With reduced clay wastage, optimized energy consumption, and minimal maintenance requirements, the extruder helps reduce per-unit production costs.

3. Faster ROI for Small Plants

Smaller manufacturers can scale up without investing in oversized equipment. This machine offers an accessible entry point to automation and higher productivity.

4. Flexible Operation

The machine’s modular design means it can be moved, adapted, or upgraded with ease as your production needs evolve.

Applications Across the Brick-Making Industry

The KeLi compact vacuum extruder is suited for:

1. Clay brick and tile production

2. Fire-resistant brick manufacturing

3. Eco-bricks using recycled materials

4. Mobile brick-making units in rural or developing regions

Its adaptability makes it a go-to choice for startups, small factories, and regional construction firms seeking to modernize their production capabilities.

Sustainability Through Smarter Machinery

KeLi Machine is deeply committed to sustainable innovation. By reducing energy use, material waste, and carbon emissions during the brick-forming process, our compact vacuum extruders contribute to:

1. Greener construction practices

2. Better use of raw materials

3. Minimized environmental footprint

In a world moving toward carbon neutrality and resource efficiency, our machines help customers meet environmental goals without compromising productivity.

Why Choose KeLi Machine?

With years of expertise and a strong reputation in the global construction machinery market, KeLi Machine offers more than just products — we deliver end-to-end solutions.

Here’s what sets us apart:

1. In-depth RD capability for customized machine development

2. Fast production capacity for quick lead times

3. Global after-sales support and spare parts availability

4. Strict quality control from raw materials to final assembly

We understand the needs of modern brick manufacturers and partner with them to provide machinery that works smarter, lasts longer, and performs better.

Conclusion

The KeLi Compact Vacuum Extruder is more than a machine — it’s a strategic investment for any brick-making business looking to enhance efficiency, output quality, and profitability. With its compact design, advanced features, and unmatched reliability, it is a true cornerstone for the future of clay brick production.

Whether you're just starting your brick plant or looking to upgrade your current setup, KeLi Machine is here to support your journey with machinery that delivers performance, sustainability, and peace of mind.

Contact us today to learn more about our compact vacuum extruder models or to request a quote tailored to your production needs.

E-mail: 13961552599@163.com