The report "Reactive Hot Melt Adhesives Market by Resin Type (Polyurethane, Polyolefin), Substrate (Plastic, Wood), Application (Automotive Transportation, Doors Windows, Furniture Upholstery, Lamination, Textile), Region - Global Forecast to 2028", is growing at a high rate due to the increased demand from various applications. The global reactive hot melt adhesives market size was USD 1.6 billion in 2022 and is projected to reach USD 2.6 billion by 2028, at a CAGR of 7.5% between 2023 and 2028. In the market for reactive hot melt adhesives, Asia Pacific is in the lead. Manufacturing and industrialization have surged because of the Asia Pacific region's several nations experiencing swift economic growth. This has consequently increased demand across a range of industries for sophisticated adhesive solutions like reactive hot melt adhesives. Reactive hot melt adhesives' increased performance, adaptability, and application efficiency are all a result of technological developments in the industry. Improvements in curing technology help to make curing procedures quicker and more effective. One example of this is the creation of adhesives that cure more quickly, allowing for speedier manufacturing cycles across a range of sectors. These days, certain reactive hot melt adhesives come with dual-cure systems that combine UV (ultraviolet) and hot melt curing technologies. This enables improved control over the curing process and offers versatility in bonding various materials.

Browse in-depth TOC on "Reactive Hot Melt Adhesives Market"

408 – Tables

56 – Figures

334 – Pages

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=222009468

Polyurethane segment is expected to hold largest share of the reactive hot melt adhesives market during the forecasted period.

Polyurethane reactive (PUR) hot melt systems typically serve as one-component adhesives, rapidly bonding to various substrates. Once applied, PUR initiates cross-linking, achieving 50%-80% of its ultimate bond strength within 3-6 hours, with a complete reactive cure expected within 24-36 hours post-application, influenced by air and substrate moisture conditions. These bonds are very strong and have exceptional heat resistance, cold resistance, and moisture-, cold, and moisture resistance.

Plastic substrate segment holds the largest segment in overall reactive hot melt adhesives market during forecast period.

Reactive hot melt adhesives are used widely on plastic substrates. The unique characteristics of reactive hot melt adhesives make them well-suited for bonding plastic substrates. They provide strong, durable, and efficient adhesion in industries such as automotive and electronics where plastics are widely used. When exposed to heat, reactive hot melt adhesives undergo a reactive process, often involving crosslinking. This results in a bond with enhanced strength and durability, which is crucial for applications with a robust connection, such as in the assembly of plastic components in automotive or electronics.

Request Sample Pages: https://www.marketsandmarkets.com/requestsampleNew.asp?id=222009468

Automotive Transportation is the fastest-growing application of the global reactive hot melt adhesives market during forecasted period.

In the automotive sector, reactive hot melt adhesives find broad application in bonding diverse components, such as plastic and metal parts. They play a crucial role in enhancing structural integrity, reducing noise, and streamlining assembly processes. These adhesives are extensively employed to create lightweight designs, enhance performance, and construct structures using a variety of materials like carbon fiber composites, glass fiber-reinforced composites, aluminum, and other multi-material combinations.

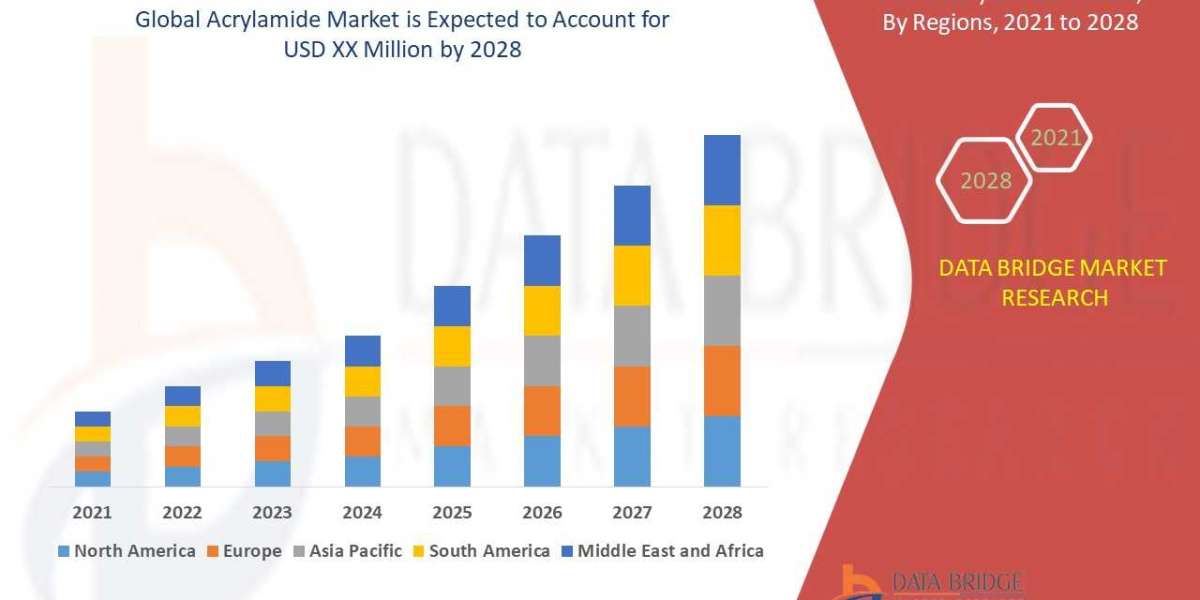

Asia Pacific region likely to account the largest share of the global reactive hot melt adhesives market during forecasted period.

Asia Pacific is one of the largest reactive hot melt adhesives markets, in terms of both value and volume, and is projected to grow significantly during the forecast period. The thriving construction industry, propelled by urbanization and infrastructure development, significantly contributes to the demand for these adhesives. Their applications extend to bonding materials in construction, furniture, and related sectors. Notably, the automotive industry, a key consumer of reactive hot melt adhesives, has witnessed remarkable growth in the Asia Pacific region. The increased utilization of these adhesives for purposes like lightweighting and structural bonding in the automotive manufacturing process has further fueled their demand.

Reactive Hot Melt Adhesives Companies

The key companies profiled in this report are Henkel AG Co. KGaA (Germany), The Dow Chemical Company (US), H.B. Fuller Company (US), Jowat SE (Germany), and 3M (US).

? Top 10 Key Players in the Reactive Hot Melt Adhesives Market

Henkel AG Co. KGaA (Germany)

A global leader in adhesive technologies, Henkel offers a diverse range of RHMAs under its Technomelt brand, catering to industrial and consumer applications.H.B. Fuller Company (U.S.)

Offers innovative RHMA solutions for automotive, packaging, and electronics, with strong RD focused on performance and sustainability.3M Company (U.S.)

Provides specialty RHMAs for high-performance bonding applications in aerospace, electronics, and medical devices, known for reliability and innovation.Bostik (Arkema Group, France)

A significant player in the adhesives market with RHMA solutions tailored for wood processing, transportation, and flexible packaging.Jowat SE (Germany)

Known for high-performance reactive PUR hot melts used in wood, furniture, and textile applications, offering both durability and eco-friendly solutions.Sika AG (Switzerland)

Provides RHMAs for construction and automotive sectors, emphasizing structural bonding and high durability under extreme conditions.Evonik Industries AG (Germany)

Supplies key polyurethane raw materials and solutions used in RHMAs, supporting advanced formulation development across sectors.Ashland Global Holdings Inc. (U.S.)

Focused on specialty adhesives and chemical formulations, Ashland contributes to the RHMA value chain with high-performance polymers and cross-linkers.Franklin International (U.S.)

Offers reactive hot melt products under the Titebond® brand, primarily serving the woodworking and construction industries.Tex Year Industries Inc. (Taiwan)

A fast-growing Asian player in the hot melt adhesives space with a strong presence in electronics and packaging markets, expanding globally.

Inquire Before Buying: https://www.marketsandmarkets.com/Enquiry_Before_BuyingNew.asp?id=222009468

? Market Analysis Trends

Automotive Sector Driving Growth:

RHMAs are heavily used for lightweight bonding, NVH (noise, vibration, harshness) control, and interior applications in electric and conventional vehicles.Sustainability in Focus:

The solvent-free and low-VOC nature of RHMAs aligns with green building certifications and environmental regulations, boosting adoption.Electronics Flexible Devices:

With miniaturization and flexibility demands in consumer electronics, RHMAs provide excellent bonding without compromising device integrity.APAC Leads Demand Surge:

The Asia-Pacific region, particularly China, South Korea, and India, is seeing rapid RHMA adoption due to booming manufacturing and infrastructure.Rise of Polyurethane-Based RHMAs:

PUR-based reactive hot melts dominate the market due to superior strength, heat resistance, and long-lasting bonding under stress.